How Robotic Palletizing Saves Backs and Boosts Output in the Warehouse

In many warehouses, people are still lifting, twisting, and stacking the hard way: back braces on, painkillers in lockers, and overtime on the schedule.

Robotic palletizing and AMRs (autonomous mobile robots) offer a way to eliminate repetitive strain in warehouses, smooth out material flow, and grow output without burning people out. This Verdusco Automation article shows how these systems work, what they fix, and why mid-sized facilities can adopt them without fear.

Let’s begin.

The Hidden Costs of Manual Palletizing You Feel Every Day

Watch a manual line at 10 AM. Then again at 3:30 PM.

Does the rhythm stutter?

By the end of a shift—when shoulders burn, backs throb, and pallets lean unevenly—you can see the toll. The walk back from the pallet is slower. The pause between cases stretches. The slip in pace doesn’t show up in a spreadsheet, but it’s carved into the unfinished orders sitting at the dock.

Operators often joke, “I’m 38, but my back feels 70.” But you see the truth behind the humor:

Lost minutes: Workers slow down after hours of repetitive lifts. Ten seconds here, twenty there. Multiply that across hundreds of pallets, and you’ve lost hours of throughput every week.

Medical costs: Strained backs and shoulders trigger workers’ comp claims, doctor visits, and insurance hikes. According to OSHA, musculoskeletal disorders account for nearly a third of warehouse injuries, draining budgets as much as bodies.

Error-driven waste: Fatigue leads to mis-stacked pallets. One crooked load can mean damaged goods, rejected shipments, or rework that eats into margins.

Overtime creep: When throughput slips, schedules stretch. Teams limp into overtime, burning payroll dollars just to keep up.

That’s more than pain talking. It’s a warning siren that your output, your budgets, and your team are absorbing costs that should never fall on human bodies in the first place.

It’s not just discomfort. It’s your output slipping away.

A Smarter Way to Move, Stack, and Keep Work Flowing: Robotic Palletizing + AMRs (Autonomous Mobile Robots)

Let’s introduce you to the tools built to remove the strain and hesitation that slow your warehouse down.

Robotic palletizing takes over the most punishing work. They perform a smooth lift and a clean stack and place every layer with the same precise force, hour after hour. They remove the risk of sudden injury and the burden of chronic fatigue, keeping teams focused on oversight, maintenance, and higher-value tasks.

But a palletizer is only as good as its feed. This is where autonomous mobile robots shine.

AMRs are self-driving carts that use intelligent routing to ferry materials from production lines to the palletizing station. Then carry the finished pallets to the staging area or dock. No magnets. No fixed tracks. They map your building, navigate obstacles, and deliver loads exactly where they need to go.

The result of integrating robotic palletizing and AMRs is a steady, uninterrupted line that doesn’t choke on manual lifts or traffic jams.

No pileups. No exhausted backs. Near-zero incident reports related to lifting.

The Numbers That Quiet Any Doubt: Time, Output, and Real Savings

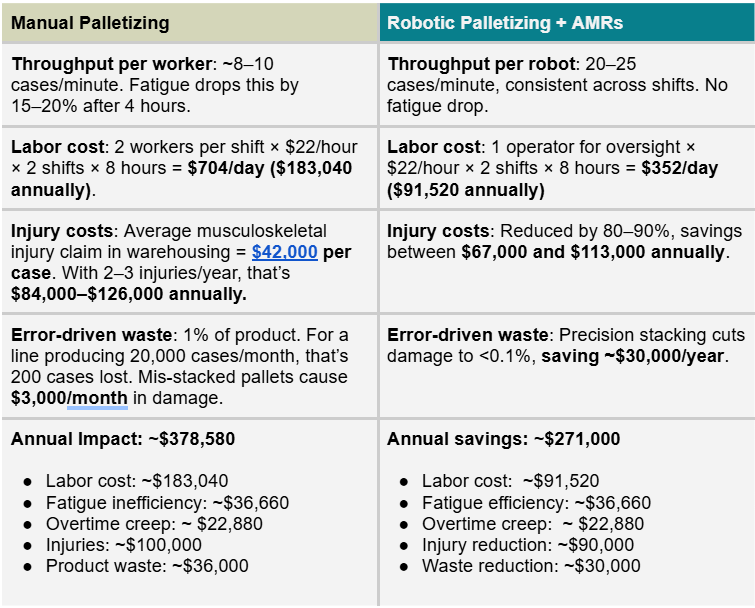

Let’s take a mid-sized bottling facility running two shifts per week, palletizing bottled beverages for distribution. Here’s a manual vs. automated operations performance comparison.

With an investment of $250,000–$500,000 and annual savings of ~$271,000, the payback period is 12-24 months. After that, savings compound year after year.

You protect workers, keep production flowing, and show ROI with clean, simple math.

Take the First Step to Fix the Back-Breaking Bottlenecks

Trying to find an “automation integrator near me” and getting nowhere?

Verdusco Automation helps warehouses shift from “barely keeping up” to operating with confidence. We build solutions that are both savvy and affordable, with a focus on real productivity gains, safer workflows, and employees who finally get to leave the floor standing tall. Whether you need to eliminate repetitive strain in warehouses or improve flow without adding headcount, we’re here to make the path easy.

Three services we provide for this transformation:

Integration and deployment of robotic palletizing systems tailored to your existing line.

AMR fleet planning and installation to automate internal movement quickly and safely.

Control system design and modernization so new automation plays well with what you already have.

Step into a plant where workers finish shifts without pain, pallets roll out with consistency, and you’re no longer fighting fires to hit shipping windows.

Book a call or walkthrough to map out where robotic palletizing or AMRs can deliver fast wins.

Contact Verdusco Automation today!

📩: https://www.verduscoautomation.com/contact

____________

Final Note:

This article shows what’s possible, but every facility is different. A custom analysis is always needed to calculate a precise ROI and define the smoothest upgrade path.