The Simple Shift from Messy Paper Logs to Clean Electronic Batch Records

It’s Friday. You finish another long shift. But instead of heading home, your detective work begins:

Chasing paper logs, squinting at smudged handwriting, digging through emails labeled “updated batch record,” and relying on someone’s memory for the one number missing from the spreadsheet.

Why can the data you need never be in one place?

This Verdusco Automation article is about closing that case for good, fast, and painlessly.

Let’s walk through it.

What Happens When Batch Records Live in Emails, Notebooks, and Memory

You hunt for a logbook that’s never where it should be.

Your operators debate whether they adjusted the temperature at 3:00 or 3:15.

Your inbox is clogged with files named “FINAL_batch_update_v3.xlsx,” each holding a different value.

You sent the wrong numbers upstairs. Again.

Fragmented documentation costs you too much. You can see it in the:

Hours lost reconciling numbers before reports go upstairs,

Delayed releases and CAPAs triggered by inconsistent records,

Downtime when root-cause investigations drag on,

Audit risk when FDA or ISO inspectors ask for proof, and tribal knowledge is the only answer.

Do your own math.

Pick one batch from last week. How long would it take to assemble its complete, uncontested documentation trail from start to finish?

And remember: every minute chasing paperwork is a minute not producing.

How Batch Record Automation Actually Fixes the Plant Floor

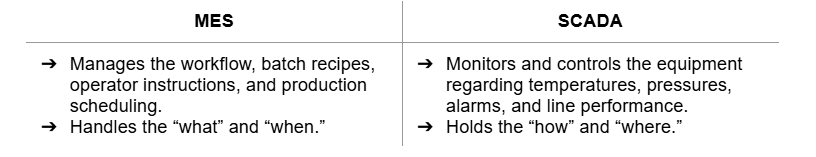

Many small pharma and food and beverage plants feel stuck somewhere between paper and digital. Some run a lightweight MES (Manufacturing Execution System). Others on SCADA (Supervisory Control and Data Acquisition). A few have both, yet still rely on paper logs. And the same question always pops up:

“If we already bought MES and SCADA, why aren’t our batch records digital?”

Here’s the reason: MES and SCADA have different functions, so they don’t magically talk to each other unless someone integrates them.

Without MES + SCADA integration, records remain fragmented. Operators still jot down numbers by hand, QA still reconciles mismatched logs, and managers still chase data across systems.

That’s where batch record automation comes in. Not as some big IT overhaul, but as the act of putting your data where it belongs: one clean, centralized digital record updated in real time.

An operator confirms a step? The system records it with a precise timestamp and a digital signature, compliant with FDA 21 CFR Part 11. A sensor reads a temperature? The value flows directly into the centralized digital record.

No transcribing. No guesswork. Just numbers updating in real time as your line runs.

The result is traceability you can trust and consistency you can build on.

Figures Behind Clean, Centralized Batch Records

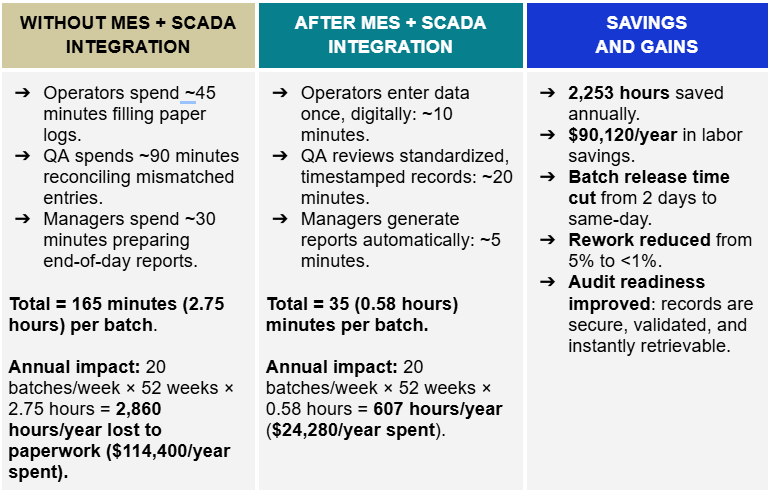

Take a small pharmaceutical plant producing 20 batches per week.

Here’s what happens:

An MES + SCADA integration project for a small plant typically costs $150,000–$200,000, depending on scope. With annual savings of ~$90,000, the payback period is less than 2 years.

After that, the system continues to deliver ROI every year.

Get Cleaner, Faster Production Records

Verdusco Automation is the integration partner small and mid-sized manufacturers trust. As industrial automation experts USA teams rely on, we make MES + SCADA upgrades simple, affordable, and plant-ready. No overhauls, no stress. Just cleaner records, smoother runs, and faster reports.

Three services we deliver to make this shift real:

Integrated Automation Solutions: Smart MES + SCADA deployments that work with your existing equipment.

Control Systems for Industrial Automation: Reliable, compliant systems aligned with FDA 21 CFR Part 1.

Industrial Automation Design: Practical, workflow-friendly designs that free operators from repetitive, straining tasks.

The result? Higher productivity, cost savings, and happier employees who no longer spend half their time chasing logs.

Contact Verdusco Automation today!

📩: https://www.verduscoautomation.com/contact

____________

Final note:

This article illustrates what can be achieved. For a precise ROI calculation, a custom analysis of your facility is needed. But the shift itself? Easier than you think.