When One Operator Calls in Sick, Does Your Line Stop? Fix That Fast

The phone rings at 6 AM.

Another operator is out.

Instantly, you run calculations in your head: Who can I move? Which line will suffer? How do we still hit today’s numbers?

When staffing fluctuates, consistency does too. Yet, you’re expected to run at 100% with 80% of the team.

This Verdusco Automation article is a practical look at how Autonomous Mobile Robots (AMRs) solve labor-dependent bottlenecks by bringing stability to the packaging, material handling, and inspection tasks that define your day in a manufacturing plant.

The Bottlenecks You Don’t See Until Someone’s Out

Let’s talk about David.

He’s the manager at a Ready-to-Eat (RTE) plant. Products include prepackaged sandwiches and wraps, refrigerated pastas and entrees, fresh salads, and meal kits. His plant runs three shifts with 220 people. Every role matters.

When an inspector is out, every package must wait because seal integrity, labels, and presentation are verified manually. That delay pushes back the schedule.

If the cart runner for material handling is missing, ingredients don’t arrive on time. Packaging zones stall. And maintenance teams scramble.

For David, the main concern is not the justified absenteeism. But the chain reaction it unlocks. Every delay costs the product its freshness, compliance, and margin.

He realized his process cannot depend on people being perfectly present every day.

How Do Autonomous Mobile Robots (AMRs) Make a Difference

Since AMRs entered the market, they’ve helped manufacturers like David stabilize their material handling, packaging, and inspection operations.

At his ready-to-eat meal plant, AMRs roll between packaging and cooling stations, hauling finished trays automatically. Scanners verify every label. Data from seal testers and weight checkers flows straight to the dashboard. No one’s chasing clipboards. No one’s guessing what’s next.

The same results show up across other industries, too:

In pharmaceutical plants, AMRs move sterile batches between inspection and storage, tremendously reducing contamination risks.

In automotive facilities, they deliver components to assembly zones as needed. No waiting, no mix-ups.

And in defense manufacturing, they handle secure material transfers through restricted areas with full traceability.

That’s what plant automation does: It builds reliability into the process itself.

AMRs step in when staffing fluctuates, keeping operations consistent, data accurate, and targets on track.

They don’t replace people. They reinforce them, ensuring production never stalls because someone’s missing.

Measuring the Payback

Let’s stay with David.

Every week, he’s short at least four operators from critical areas: inspection, packaging, and material handling.

Their absence is felt everywhere. Packaging slows. The conveyor backs up. QA is chasing samples instead of reviewing them. Everyone’s hustling to ship what they can. The rest? Delayed, with extra overtime to catch up.

The missed shipments, the overtime, and the stress of wondering who might call in sick tomorrow led David to take action. He decides to invest in Autonomous Mobile Robots, not as a contingency, but as a permanent part of the operation.

AMRs check three critical boxes for him and his team:

Reliability: Show up on time to every shift.

Traceability: Every label scanned, every package verified, every movement logged.

Flexibility: Easily adapt to shift changes and production volumes.

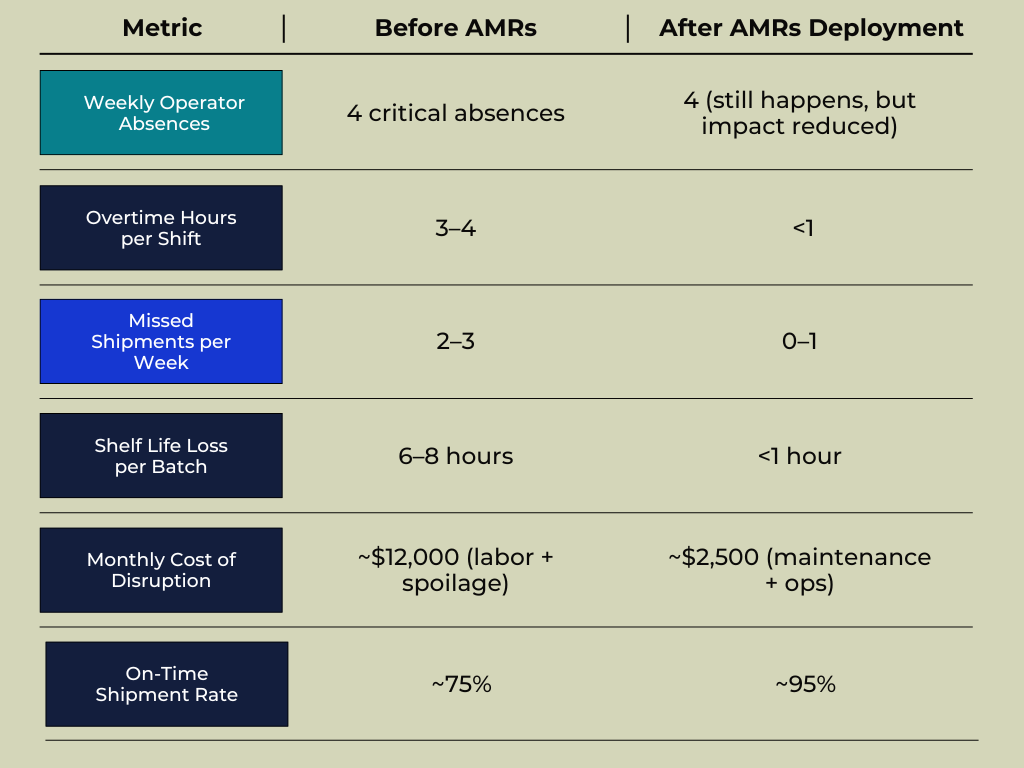

Now, picture the same plant three months after integrating Autonomous Mobile Robots (AMRs). Here’s what the turnaround might look like after the first month:

David didn’t solve absenteeism. He found consistency.

When AMRs are part of a plant’s DNA, they keep the line moving, targets within reach, and people informed. Every single day. And the money shows up fast in steadier output, happier teams, and production targets that stop depending on luck.

Turn Stability into Standard Practice

Much like David, what you really want is to hit your targets without chaos, overtime, or constant reshuffling every time someone takes an unexpected day off.

You want a plant that runs steady, no matter what.

That’s exactly what AMRs deliver. They smooth out the highs and lows, keeping packaging, handling, and inspection consistent even when staffing fluctuates.

Verdusco Automation helps manufacturers make that consistency permanent. We design and integrate systems that fit your process and grow with it.

Our focus:

AMR deployment and integration: CabraMove AMRs that move materials and data seamlessly between zones.

Control systems and dashboards: Real-time visibility for smarter, faster decisions.

Automation design: Streamlined layouts that boost throughput and reduce downtime.

Less firefighting. More flow.

Contact Verdusco Automation today!

📩 https://www.verduscoautomation.com/contact

Note: This article is for reference only and aims to showcase the potential of AMRs in manufacturing. To understand how automation can perform in your specific facility, a custom analysis is essential.