Zero Downtime. Zero Errors. Zero Injuries. Are You Ready?

Your team just recovered burnt circuits after a 3-hour line freeze. Now, the time to crunch the day’s numbers begins. That familiar pit in your stomach returns. The results glare back: deep in the red. Again.

Beyond the circuit fiasco? Shipping lagged thanks to a stalling conveyor. Another batch was scrapped by a calibration error. And the gut punch: a technician slipped resetting a jammed line.

“Can I have zero downtime, zero errors, and zero injuries just once?” you whisper.

YES, YOU CAN with the new reality powered by smart automation.

In this Verdusco Automation article, we’ll map your path to triple-zero by uncovering:

Why factories crave smart automation now.

5 game-changing technologies.

Your no-sweat leap into the future.

Let’s dive in.

Why Today’s Factories Crave for Smart Automation

In the automotive sector, a Tier 2 supplier we met had to pause delivery for 3 days because a faulty sensor failed to flag a line misalignment.

In a medium-sized beverage plant, inconsistent line speeds ruined over 300 bottles of premium juice in one shift.

In a food plant, one injury on a packaging line halted operations, triggered investigations, and rippled through the supply chain.

The cost? Beyond dollars: eroded trust, team burnout, lost contracts. That’s why so many factories today long for change. They’re are screaming: How do we stop this?

The answer is smart automation. With real-time data, integrated systems, and intelligent robotics, it turns chaos into clarity, noise into flow, and reaction into prediction.

Run your numbers:

Cost of 1 hour downtime?

Annual scrap/rework?

True price of 1 preventable injury?

Your factory craves relief, demands precision, and the tools it deserves.

The Quest for Zero Downtime, Zero Errors, and Zero Injuries

Triple-zero is being forged today by technologies that see more, predict better, and act smarter. Here are 5 game-changers transforming vision into reality:

1) Intelligent Autonomous Mobile Robots (AMRs) for Injury-Free Material Movement

Feel the Pain: The strain in your warehouse team's backs after miles of manual cart pulling. The echoing clang of a forklift clipping a rack. The frantic search for missing WIP.

The Smart Gain: AMRs glide silently, 24/7, knowing exactly where every part needs to be. They dodge obstacles, eliminate heavy lifting, and slash forklift truck risks.

The Value: Think $25k-$75k per AMR (scalable). ROI? Often less than 9 months via labor redeployment, reduced damage, and relentless uptime.

2) AI-Powered Predictive Maintenance as a Crystal Ball for Zero Downtime

Feel the Pain: The sinking feeling of seeing “Critical Failure” flash on the HMI. The frantic phone calls scrambling for parts and techs.

The Smart Gain: Sensors send warnings weeks before any failure (a motor bearing warming, a hydraulic pressure dip, etc.). Maintenance becomes planned, precise, and peaceful. You get a sixth sense.

The Value: Solutions start around $50k (IoT sensors + platform). ROI manifests as slashed emergency repair bills, optimized spare parts, and the golden prize: predictable production flow.

3) Machine Vision & AI Quality Control Against Errors

Feel the Pain: The accelerated heart rate over customer complaints. The sight of products discarded. The tedious, eye-straining monotony of manual inspection.

The Smart Gain: Cameras and AI spot microscopic defects invisible to the human eye—a cracked vial, a misaligned label, a missing component—at lightning speed, 100% of the time.

The Value: Systems range from $30k (focused application) to $150k+ (full line). ROI flows from eliminated scrap, zero recall costs, and unwavering brand integrity.

4) Adaptive Process Control for Self-Optimizing Production Lines

Feel the Pain: The frustration of tweaking settings amid conditions changes. The wasted minutes after a product changeover while operators dial in parameters. The nagging inconsistency in output quality.

The Smart Gain: The smoothness of a system that continuously monitors and automatically adjusts settings (temperature, pressure, speed) in real-time to maintain perfect quality, regardless of variations. Changeovers become seamless. Consistency becomes the default.

The Value: Integration costs vary ($40k-$200k+), but gains in yield, reduced waste, and energy savings deliver compelling, ongoing ROI.

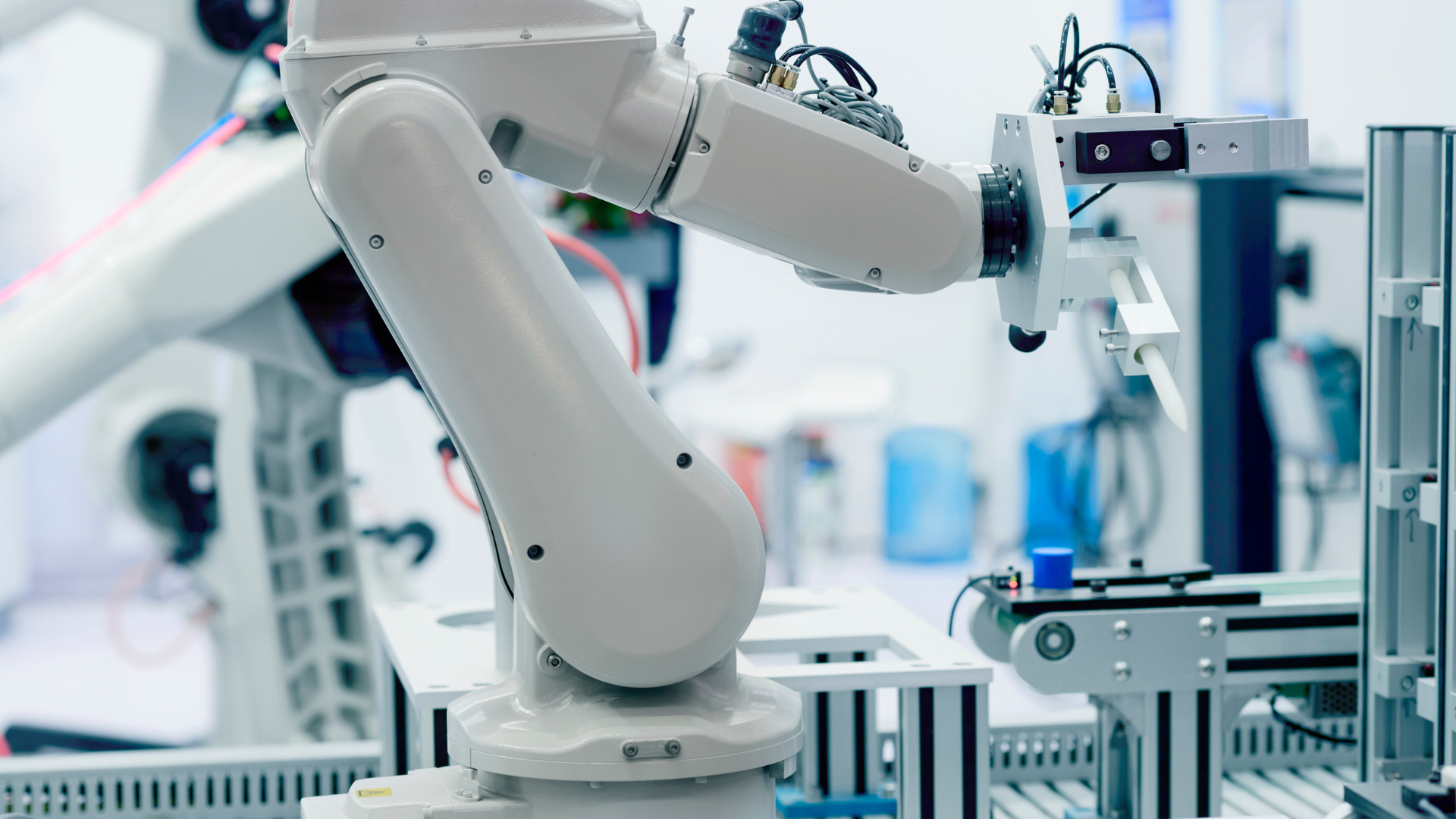

5) Collaborative Robotics (Cobots) as Tireless and Safe Production Partners

Feel the Pain: The wince as an operator reaches deep into a machine for a repetitive pick. The fatigue set in during the 10th hour of intricate assembly. The risk zone around traditional robots.

The Smart Gain: Cobots work safely alongside your team, handling the tedious, the precise, or the ergonomically challenging tasks (welding, polishing, and packing delicate items). They stop instantly on contact.

The Value: Cobots start around $20k (arm + tooling). ROI shines through increased throughput per shift, reduced worker fatigue/injury, and redeploying talent to higher-value work.

What About the Upfront Cost?

When the technology is selected, installed, and deployed as it should, the investment pays for itself by sparing you the massive and recurring price tags from downtime, errors, and injuries.

We call it a fundamental shift towards resilient profitability.

Your No-Sweat Automation Jumpstart

What if tomorrow looked different?

You’d see lines running with no hiccups. You’d hear controlled alerts instead of panic alarms. You’d feel confident knowing your team isn’t chasing ghosts anymore.

Verdusco Automation has helped dozens of companies go from patchy and reactive to smooth and predictive. We’re not here to sell you hype. We’re here to engineer calm.

Our automation solutions are crafted to:

Ease worker fatigue

Minimize waste and unplanned downtime

Bake safety into every task

We support you with:

Industrial Automation Design: Tailored systems scaled with your needs.

Integrated Automation Platforms: Bringing harmony to your processes.

Autonomous Carts & AMRs: Let your people focus on value, not hauling.

"The best time to plant a tree was 20 years ago. The second best time is now." — Chinese Proverb

Build your zero-downtime factory today.

Reach out to Verdusco Automation: