How Small Plants Can Compete with Big and Grow Steadily in 2026

You show up early. You stay late. You push the team. And still, targets slip. Your hands feel tied in a knot you can’t undo. When sales demand more volume, frustration builds. Despite everyone’s effort, the plant stalls.

This Verdusco Automation article shows you how to untangle the mess with three practical solutions. Each one helps small plants move faster, protect margins, and grow sales without chaos.

With the Right Upgrades, Even the Smallest Plant Can Run Like a Top-Tier Competitor

Automation is no longer reserved for giants. Today, it’s a practical lever that helps smaller plants regain control, stabilize output, and see margins finally grow. But before seeing any real change, strategic enhancements should be done to make the existing team and facilities more effective.

Let’s show you how automation makes a difference by setting up the stage in a mid-sized plant running a single packaging line (filling, capping, labeling, case packing), operating one shift, and facing seasonal demand spikes with tight margins.

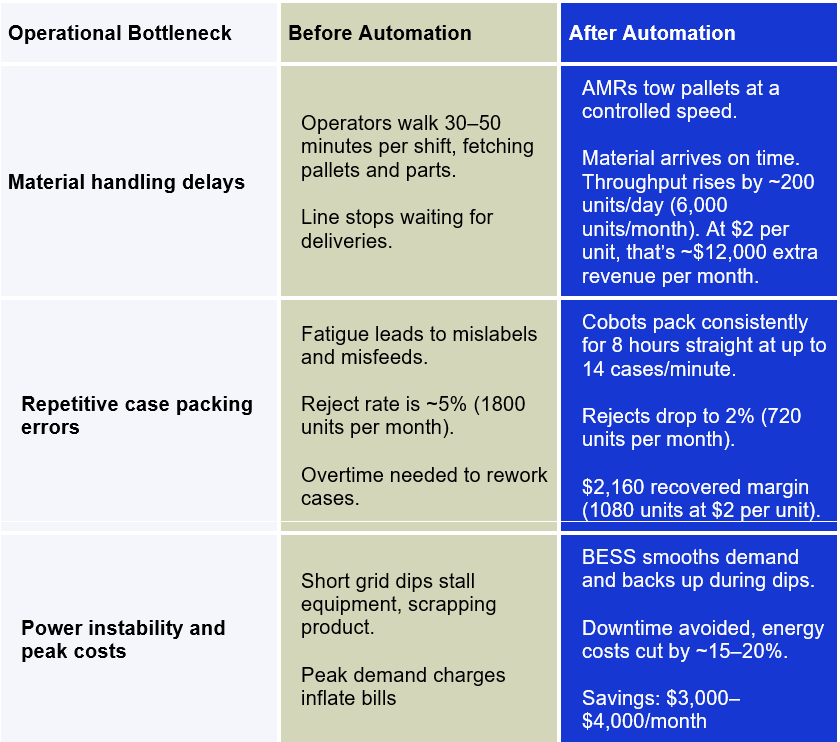

The daily struggles are familiar: operators walk long distances to fetch pallets, labeling errors increase late in the day, and short power dips force costly line stops.

If this feels close to home, you’re not alone.

Here are 3 moves to boost your plant’s performance in 2026:

Robotics that Handles Repetitive Tasks

What it does: Autonomous mobile robots (AMRs) move pallets and parts between staging and the line. Collaborative robots (cobots) take over repetitive, error-prone tasks like labeling and sealing.

Why it matters: When operators spend large chunks of their shift fetching pallets or repeating the same motions, value slips away. Fatigue sets in. Errors follow. Robotics steps in to absorb that strain.

AMRs tow pallets at a controlled speed, scanning the area to avoid jams. In one beverage case study, a fleet of 5 AMRs moved 44 pallets per hour with 99% uptime, replacing forklifts and freeing 9 operators.

Cobots bring consistency where hands get tired or rushed. At Bob’s Red Mill, a cobot palletized up to 14 cases per minute for eight hours straight, easing labor shortages and improving quality.

Immediate effect: Steadier throughput. Fewer rejects. Operators focused on work that actually moves the needle.

BESS as a Shield Against Power Instability

What it does: Battery Energy Storage Systems (BESS) store energy during low-demand periods and release it during peaks or brief outages, keeping production running.

Why it matters: The grid is aging, and for a small plant, a five-minute brownout can ruin a whole batch of product. BESS kicks in instantly when the grid flickers or when peak-hour tariffs attempt to hijack your budget.

A U.S. manufacturing plant with a 500 kW BESS cut peak demand by 200 kW, reducing electricity expenses by 18% annually.

Immediate effect: Lower energy bills. Fewer unplanned stops. Confidence that production won’t stall when power becomes unstable.

Industrial Automation Consulting that Connects It All

What it does: Industrial automation consulting connects the dots. Consultants design pilots, integrate controls, and mentor operators. Most importantly, they identify the single bottleneck that delivers the fastest return.

Why it matters: Technology alone isn’t the answer. Without guidance, plants overspend on mismatched equipment or deploy systems their teams can’t fully use. Consulting ensures automation is scoped, installed, and adopted correctly.

Working with a trusted automation partner helps managers know where to start and what to avoid.

Immediate effect: Smoother rollouts. Faster ROI. A plant that feels more reliable day after day.

How Automation Increases Manufacturing Sales

Operational improvements only matter if they show up in the numbers.

For our mid-sized plant, running a single packaging line producing 1,200 units/day (36,000 units/month), automation translates directly into sales growth and margin relief.

By addressing any of these three bottlenecks, the plant can see monthly gains through extra sellable units or energy savings. That’s how automation increases manufacturing sales: steadily, predictably, and without pushing people past their limits.

Leveraging Industrial Automation Consulting to Drive Small Plant Growth

Technology without guidance often becomes shelfware. Industrial automation consulting bridges the gap between good ideas and real results. This is where Verdusco Automation comes in. We partner with manufacturers to design solutions that fit their size, budget, and goals.

Three core services VA offers to support your growth:

Industrial automation design and integration: Control system design, layouts, and workflows that actually work on your floor, not on paper.

Robotics and AMR deployment: From AMRs to cobots, we integrate robotics that improve flow without disrupting operations.

Energy storage and backup power solutions: BESS systems protect uptime, reduce peak costs, and give plants control over energy volatility.

In 2026, you can lead your plant to improved operations for lasting growth.

Get started by contacting Verdusco Automation today!

📩: https://www.verduscoautomation.com/contact

____________

Final note: This article illustrates what’s possible. Every facility is different. A custom analysis is needed to calculate a precise ROI and define the right path forward. The good news? Evolution doesn’t require a giant leap. It starts with one smart move.