Not Sure If Automation Will Pay Off? Let’s Do the Math

Manufacturing is undergoing a huge transformation. The arrival of technologies such as artificial intelligence, robotics, and 3D printing has reshaped how products get designed, produced, and delivered. In a nutshell, manufacturers found a new approach to creating more customized, efficient, and sustainable solutions for their clients. And while at it, they are improving productivity, quality, and competitiveness.

You open your laptop and stare at a flashy proposal. It promises to transform your operations. There’s a lot of buzz about autonomous mobile robots, control systems, and smart platforms. Catchphrases like “revolutionary efficiency” and “seamless integration” win you over. They sound so tempting.

Then a question gnaws at your gut:

“What if I spend all this money… and nothing changes?”

The stakes couldn’t be higher. But also, what if the technology isn’t science fiction? What if it’s proven, practical, and pays you back faster than you think?

This Verdusco Automation article cuts through the fog. We’ll tackle your fears head-on and show you the concrete math behind automation ROI. You’ll justify automation investment with numbers your CFO will love and stories your ops team will believe.

Ready to make automation your next power move?

Why Automation Feels Like a Gamble

You’ve probably picked up horror stories at industry events. Or seen headlines blaring “Automation Project Fails, Costs Millions” after a cobot couldn’t handle real-world variability. Or an AMR fleet created more traffic jams than efficiencies. Or a software integration project became a bottomless money pit.

We get it. Ending up with a white elephant petrifies you. Seeing your investment sink like the Titanic, receiving skeptical stares from the board, and feeling the crushing weight of “I told you so” overwhelm you. You might as well gamble all your chips on the table, knowing you’d lose.

But the reality is that many automation projects fail because they’re rushed, overcomplicated, or disconnected from real-world needs.

At Verdusco Automation, we’ve seen it firsthand. We’ve been called to rescue botched installs, rewire confusing control panels, and simplify overly ambitious designs.

What’s the shift? Smart automation—the kind backed by user-friendly systems, tailored design, and rock-solid support—is no longer a high-stakes bet. It’s a calculated move that pays off.

And it pays off faster than most realize.

Let’s Talk Results, Not Promises: Show The Automation ROI Your CFO Will Trust

Automation ROI comes from three main streams:

➔ Labor efficiency.

➔ Increased uptime and production speed.

➔ Fewer errors and injuries.

How does it happen?

The ultimate solution depends on your areas of improvement:

Replacing the frantic clatter of manual material transport with the coordinated glide of a CabraMove AMR.

Transforming an erratic palletizing station with a precise robotic arm.

Or feeling the relief when that critical packaging line is at 98% uptime, not sputtering at 75%.

Those are the tangible shifts smart automation delivers.

Watch it in action with this relatable scenario set in a food and beverage plant:

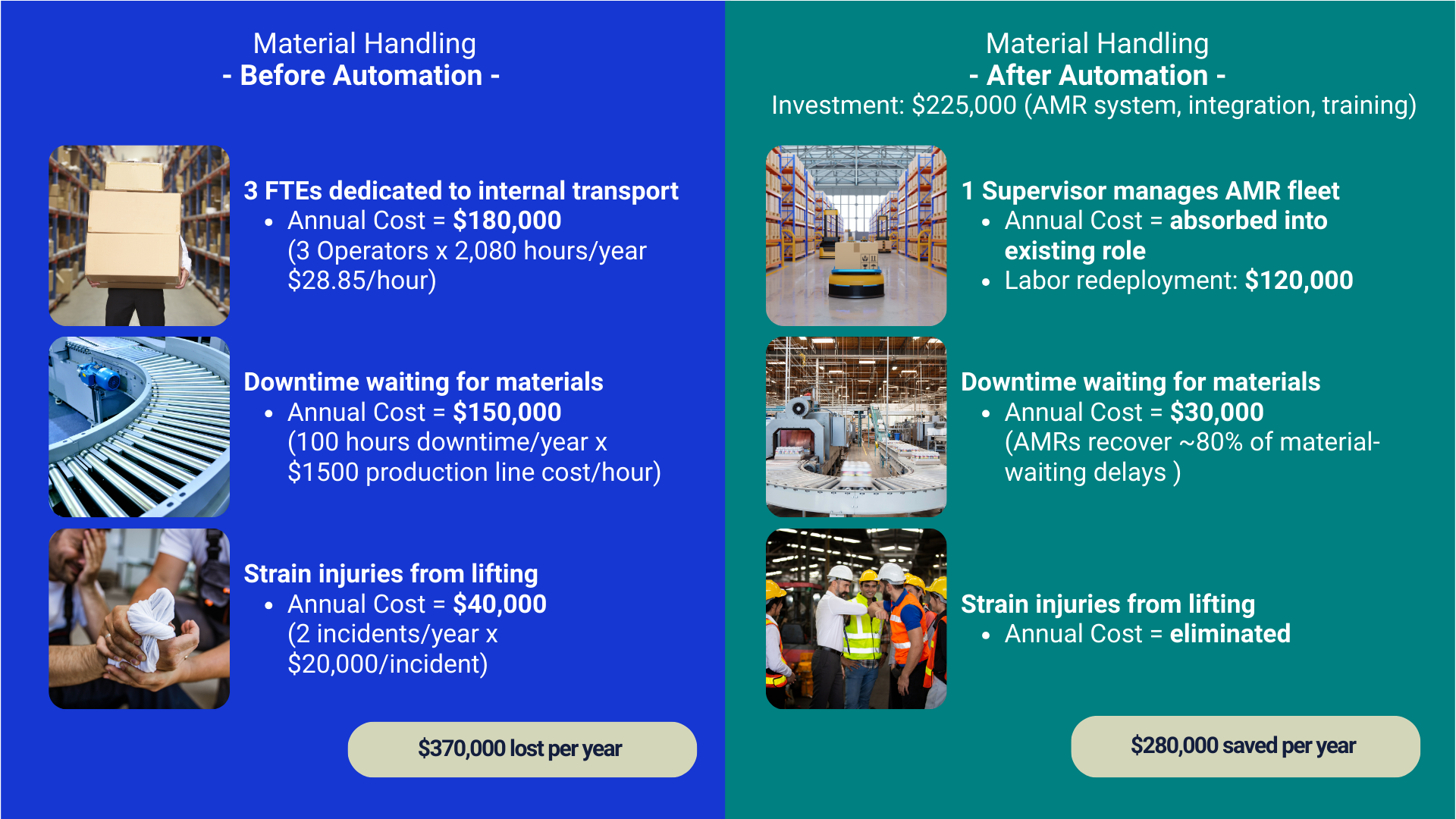

Figure 1. Material handling transformation before and after introducing automation (source: Verdusco Automation).

Saw the savings potential? And that’s just automating one process!

Now imagine your:

QA process streamlined with data-driven controls.

Manual handling replaced with collaborative robots.

Downtime tracked and tackled automatically.

How to Win Over Your Finance Team?

Don’t just pitch automation as a “smart idea.” Show them the numbers. Use these simple formulas your CFO will love:

Simple Payback Period = Total Investment / Annual Net Savings

ROI (Year 1) = (Annual Net Savings - Annual Costs) / Total Investment x 100%

Returning to our food and beverage material handling scenario, the initial investment was $225,000, and the annual savings from automation (labor, downtime, and safety) were $280,000. Insert the values into the formulas and you get:

Payback Period: $225,000) / $280,000 = 0.80 years (10 months)

ROI (Year 1) = ($280,000 – $225,000) / $225,000 × 100 = 24.4%

You’ll see a return in the very first year, not even accounting for the compounding benefits that follow. By Year 2, you’re already well into the black.

These calculations aren’t just CFO-friendly. They show automation is a measurable business case, not a leap of faith. The numbers speak for themselves.

Ready to Take the Leap? Here’s Your Next Step on How to Justify Automation Investment

Every month without automation is a month where your:

Team faces unnecessary strain.

Production risks fall behind demand.

Costs keep climbing while efficiency stalls.

By talking to an expert, you don’t just “get a quote.” You get a vision tailored to your plant’s reality. At Verdusco Automation, we don’t sell hype. We deliver clarity.

Our custom automation plans are:

Modular: Scale at your pace.

Savvy: Designed around your existing setup.

Affordable: We make smart upgrades accessible.

So, remember:

“In a time of drastic change, it is the learners who inherit the future.”

The opportunity is here. You don’t need to be a Fortune 500 company to automate. You just need the right partner. At Verdusco Automation, we ensure the math adds up—and the change sticks.

📩 Contact us today: https://www.verduscoautomation.com/contact