The Real Reason Your Shipping Times Are Falling Behind (And How to Fix It)

It’s not the demand. It’s the method.

Many small and mid-sized logistics companies blame shipping delays on labor shortages or supplier errors. But the truth lies within their own four walls: manual order picking, paper-based inventory logs, and forklift-heavy movement create constant friction. As mistakes multiply during peak hours, pallets end up where they shouldn’t be. Time is lost. Revenues fly out the dock doors.

What’s missing is not muscle but smarter movement.

How can you get it?

This article by Verdusco Automation breaks down how warehouse robots can help you escape tricky logistics to flow like clockwork.

How Much Are You Bleeding Due to Slow Order Fulfillment?

Let’s run numbers, shall we?

A mid-sized warehouse moves 5000 units/week. Picking and packing time should be 3 minutes/unit but poor routing, manual transport, and delays slower ops, Actual picking and packing reaches 5 minutes/unit.

What are the consequences?

Without factoring customer churn, losses reach almost $400k per year.

We bet that if you customize these calculations, you’ll come up with the same conclusion.

Manual methods are speed and profit killers!

How can you break the cycle and recover?

Meet the Autonomous Mobile Robots (AMRs) Advantage: You Can’t Compete with Amazon Without Them

They are fast. They are accurate. They are not here to take your job.

AMRs are mighty machines programmed to:

● Navigate warehouse floors autonomously.

● Adjust routes on the go to avoid jams.

● Pump up internal movement with little to no human intervention.

According to a Gitnux report, by running 24/7 without breaks, warehouse robots like AMRs can increase operational hours up to 30%.

Giants like Amazon saw their virtues early on. And today, their fulfillment centers heavily rely on the technology to infuse dynamism and speedy responses to a global and ever-growing demand.

When you’re running a logistics operation with razor-thin margins, every second saved is money earned. That’s the AMR advantage to improve slow order fulfillment issues.

Is Betting on Robots Worth It?

About 49% of automation projects focused on material handling report a return on investment (ROI) of 12 months or less.

For a fuller picture, let’s go over different cases where AMR adoption hastens order fulfillment.

We won’t focus on mega-corporations with billion-dollar budgets. But smart operators who said yes to the right tool at the right time.

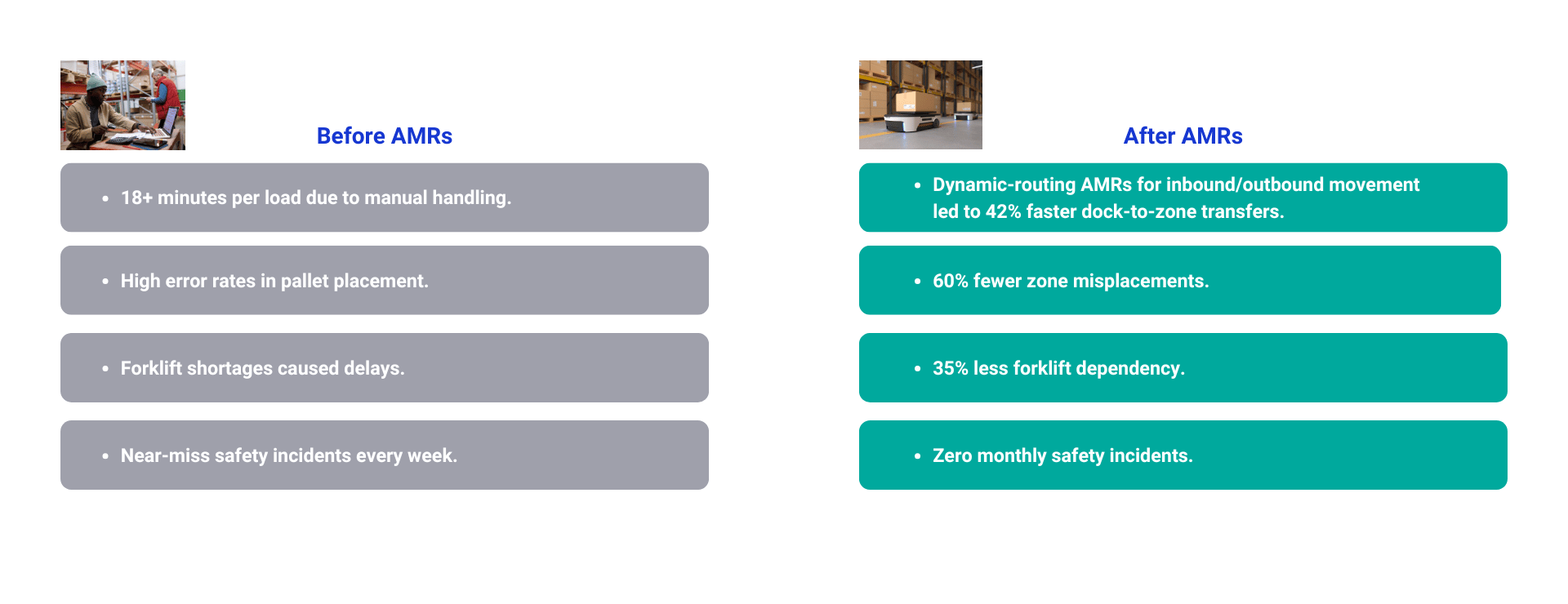

Central Freight Distributor

Facing rising pick times and overworked forklift operators. Integrating AMRs in the main warehouse turns performance by 180 degrees:

Final ROI: 10 months.

Pharma Fulfillment Center

Handling everything from over-the-counter packs to temperature-sensitive medications comes with strict FDA regulations and cleanroom protocols. Even a single deviation could trigger product recalls. Using manual cart-pushers to transport goods between storage zones and packing areas brought cross-contamination, routing bottlenecks, and high labor turnover.

Incorporating a fleet of AMRs equipped with zone-specific access rules, cleanroom-compatible builds, and automated handoff protocols at transition gates changes the situation:

Final ROI: 22 months.

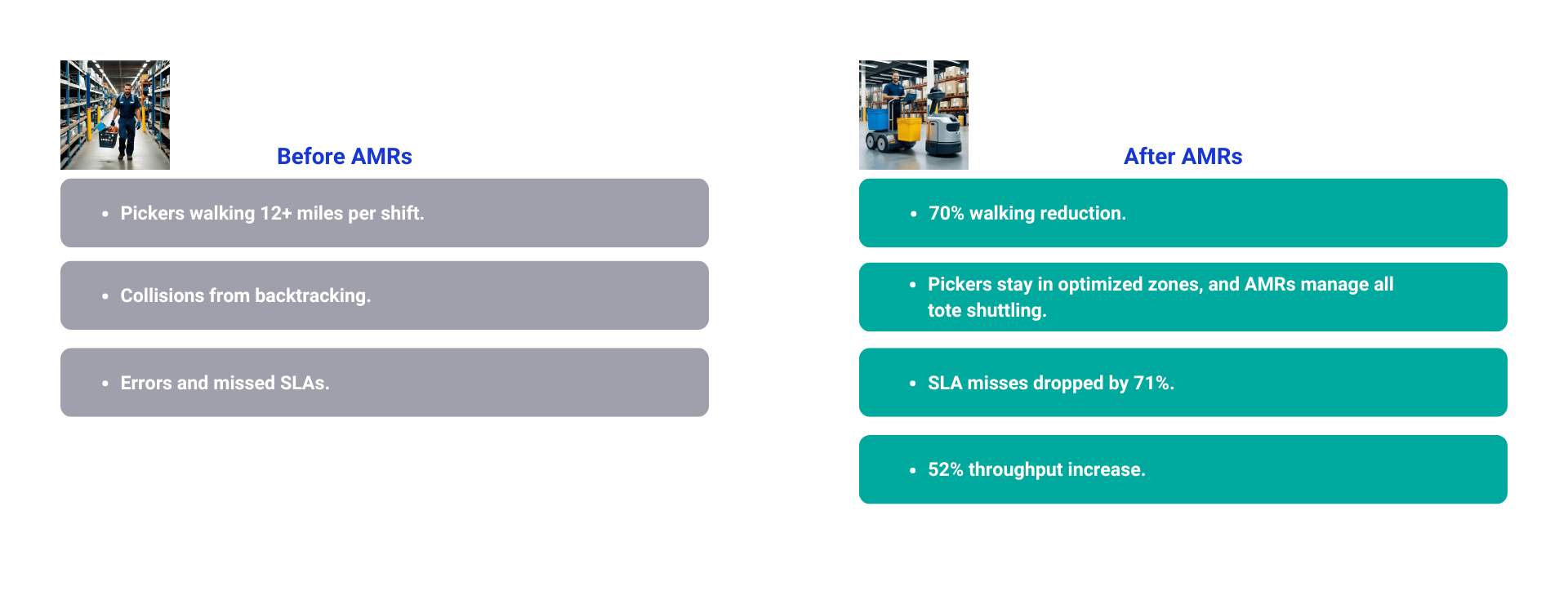

Regional Spare Parts Hub

A spare parts distributor for automotive and heavy equipment serves hundreds of SKUs from a medium-sized facility. During peak months, the warehouse processes over 3,500 daily picks. The core issues reducing order fulfillment include long-distance coverage, low throughput, and SLA violations.

Verdusco Automation would tackle the bottlenecks by installing a zone assigned for AMRs to handle tote transport between pickers and packing stations and a digital pick-to-light system synced with robot dispatching.

Final ROI: under 11 months.

The Best Technology Is Invisible When It Works

Donald Norman said that, and we fully agree!

To get faster, smarter, and safer order fulfillment in your logistics operations, warehouse robots are a must.

At Verdusco Automation, we specialize in delivering tailored automation and Autonomous Mobile Robot (AMR) solutions for logistics operators who want more than a flashy upgrade.

As a CabraMove certified partner, here’s how we help you:

➔ Perform system integration & WMS connectivity.

➔ Carry on turnkey installations.

➔ Tailor ROI-driven deployments.

📩 Get in touch now: https://www.verduscoautomation.com/contact