AI and Robotics in Manufacturing: 3 Trends You Can’t Ignore

Think your plant runs like an F1 car?

You might hit the brakes once you see how today’s AI and robotics in manufacturing are turbo-boosting operations into a new era.

Your PLC from a decade ago cannot compete.

Let’s break down the three most surprising trends you need to know, as rated by Verdusco Automation.

Ignoring them could mean drowning in rising costs, unpredictable downtime, and inefficiencies that outdated systems won’t solve. In simpler words, getting left behind for good.

Manufacturing Trends You Can’t Afford to Ignore

Is your production line an on-off mayhem?

That’s a loud call for transformation. Not tomorrow, but now.

The legacy systems that once drove your production line to success have likely rusted to the point where patching them up is no longer a viable option.

Unsure of what your next call should be?

Sit tight. We are presenting what AI and robotics are quietly doing to rebuild manufacturing into a new power era.

Buckle up!

Trend 1: AI-Driven Predictive Maintenance Is Ending Emergency Downtime

Manual inspections and calendar-based checks can’t catch unseen issues until damage is done. Repair bills skyrocket as a consequence.

Powered by AI, smart sensors and analytics predict equipment failure long before the first smoke signal.

Here’s a glimpse at the benefits:

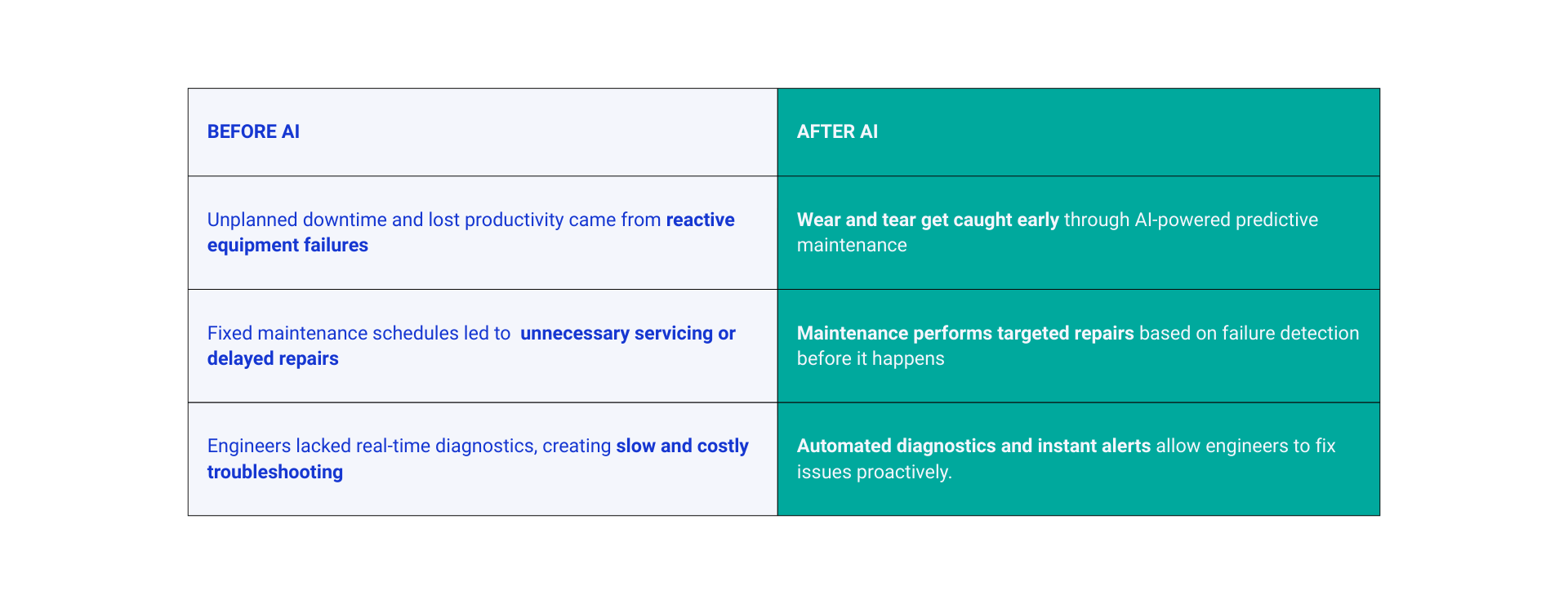

To give you a clearer picture, let’s examine the before and after snapshots for a hypothetical semiconductor manufacturer that decides to greenlight AI-driven predictive maintenance solutions.

Table 1. Before vs. After: Semiconductor Manufacturer Smart Maintenance Transformation.

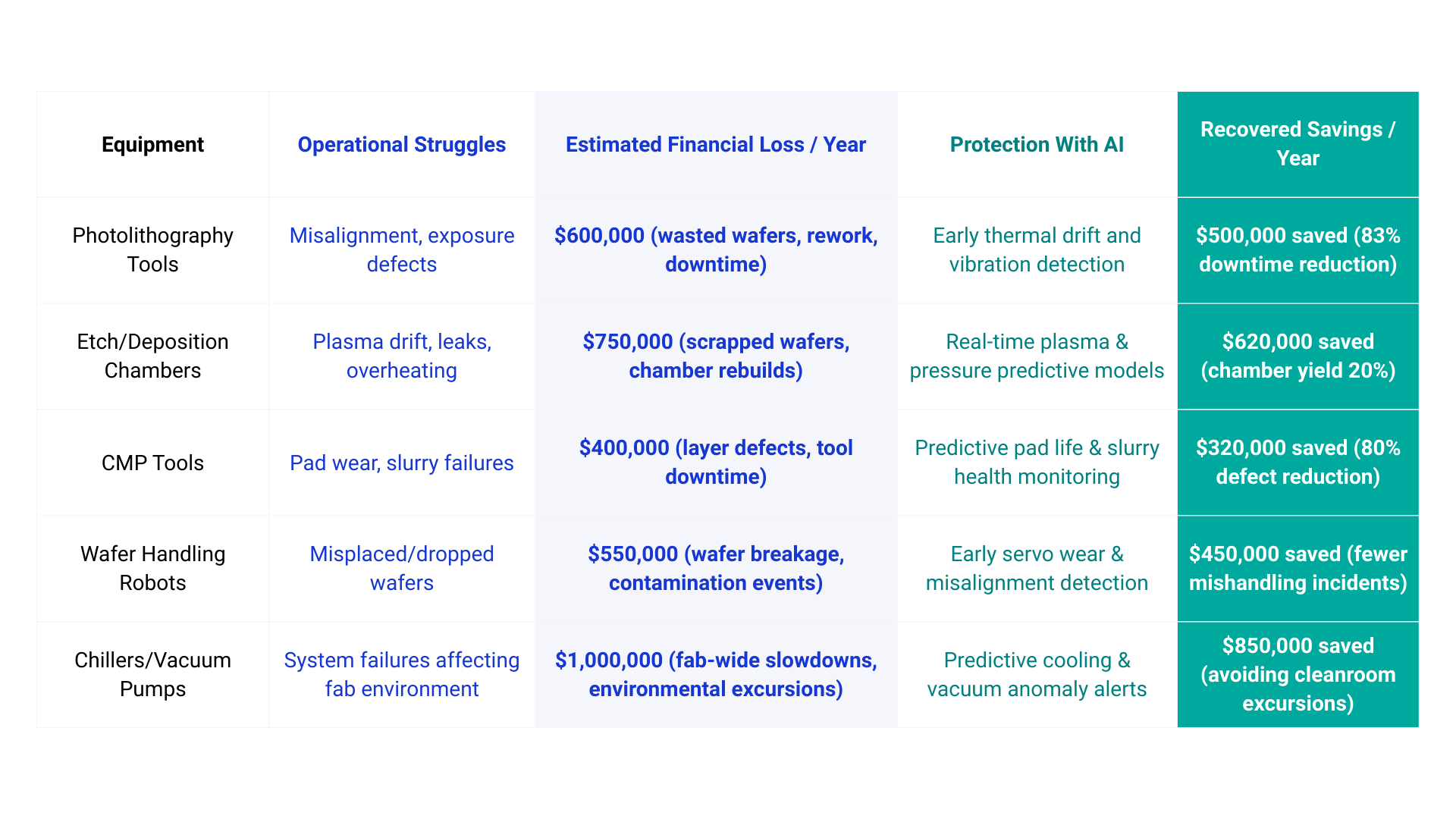

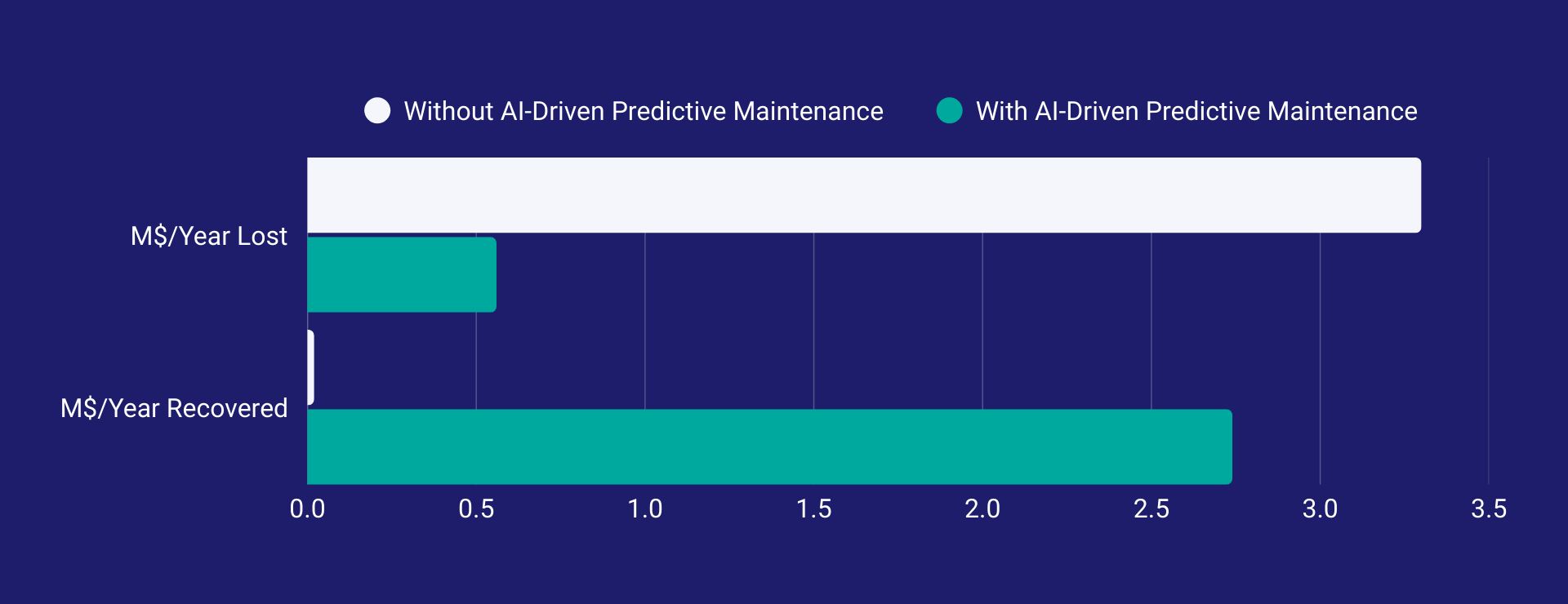

Installing predictive AI solutions can recover ~83% of the avoidable losses (roughly $2.7M per fab per year). Preventing equipment-driven disruptions pays off, protecting uptime, employee trust, and product quality!

Fig. 1. Financial Impact of AI-Driven Predictive Maintenance for the Semiconductor Manufacturer.

Putting it in perspective, predictive maintenance saves money, stress, and production schedules.

Trend 2: AI-Optimized Quality Control to Catch Mistakes Before They Matter

Human inspectors are good. AI-trained vision systems? They’re relentless.

Thanks to advances in deep learning, AI-optimized quality control now spots defects, anomalies, and micro-mistakes invisible to even the most seasoned inspector. And it happens in real-time, not hours or days after bad parts have moved down the line.

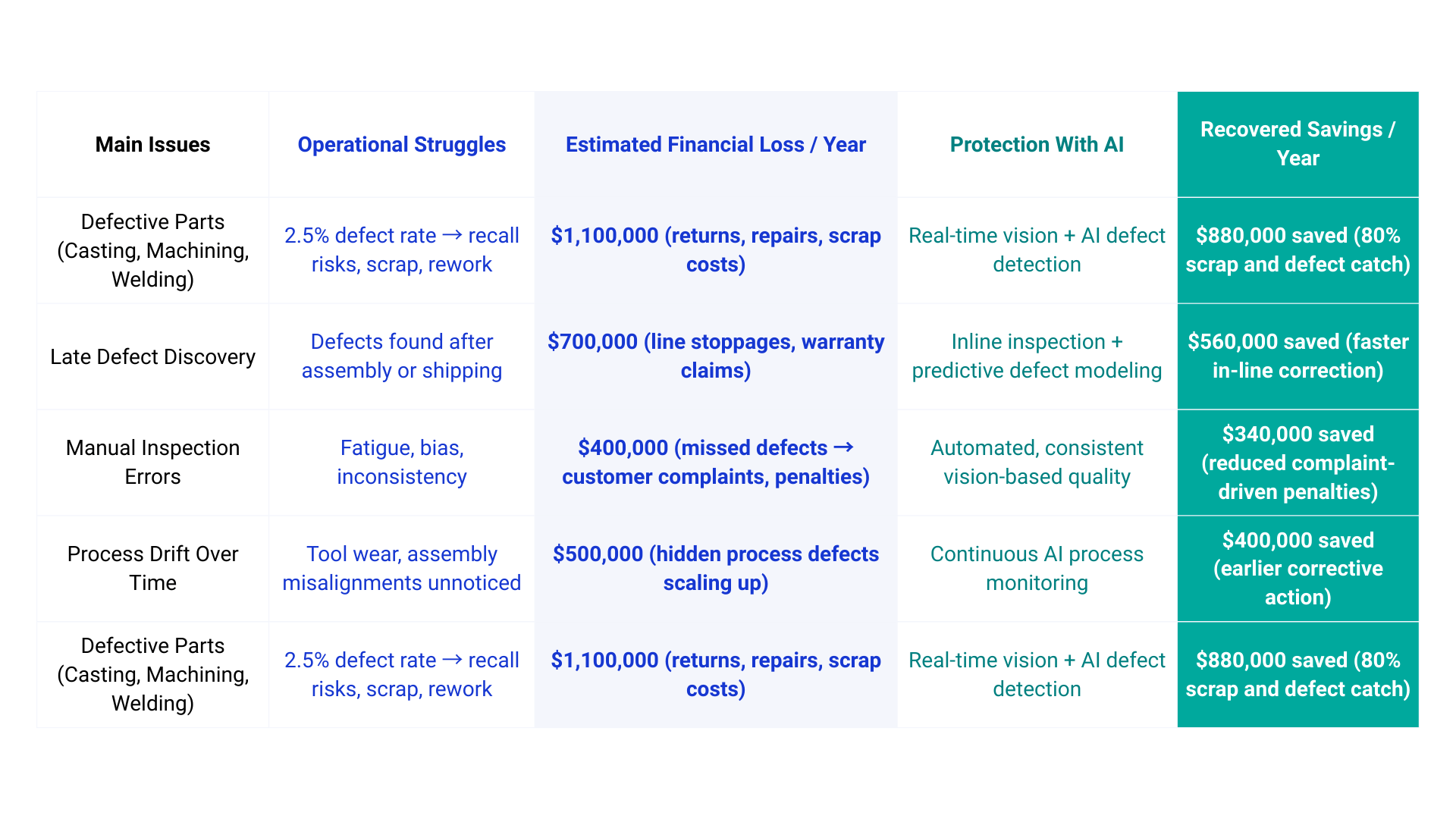

Let’s build a strong, realistic scenario based on a mid-sized automotive parts manufacturer.

Table 2. Before vs. After: Automotive Parts Manufacturer Smart Quality Control Transformation.

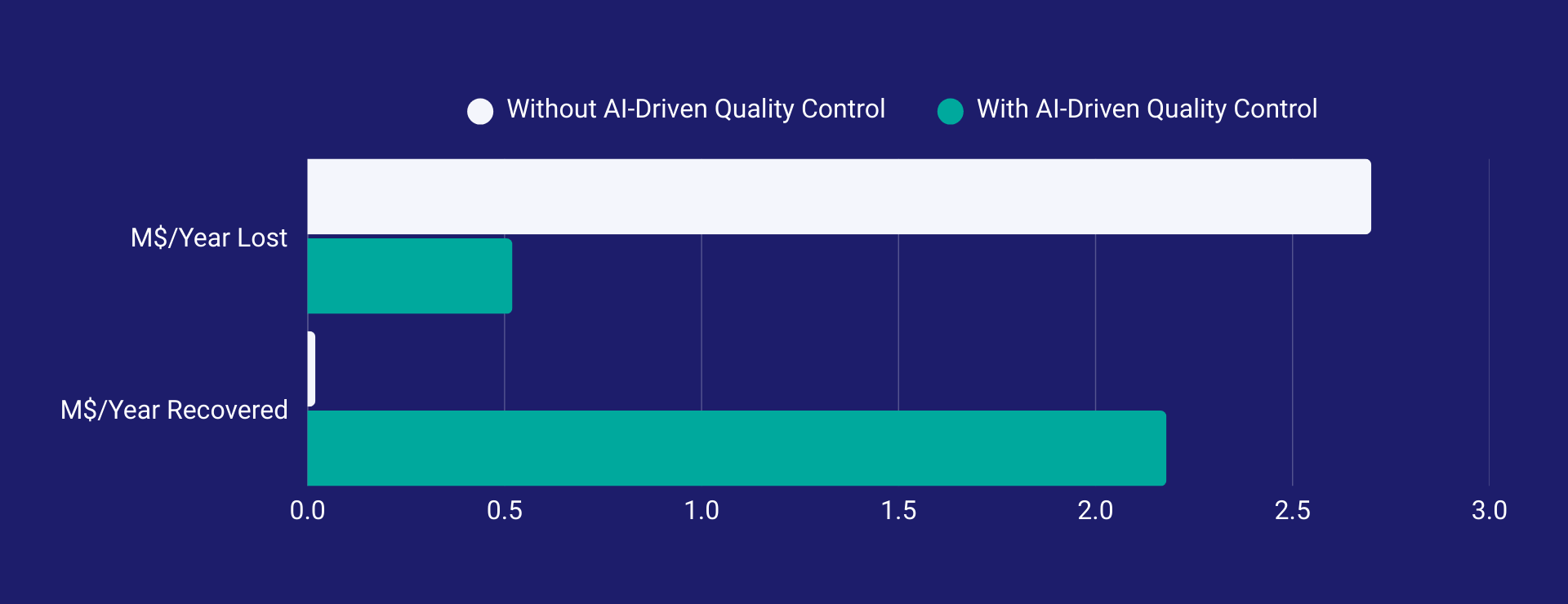

In our example, there’s the potential for an impressive annual recovery of $2.18M after introducing AI-powered quality control (~80% in savings).

Fig. 2. Financial Impact of Smart Quality Control for the Automotive Parts Manufacturer.

With smart quality control, every bad part caught early means a crisis is avoided. Moreover, manufacturers get to prevent defects and shield their brand, their margins, and their customer loyalty.

Trend 3: Autonomous Mobile Robots (AMRs) Reinvent Internal Logistics

Your factory is a busy place. But as of late, legacy setups such as fleets of forklifts, exhausted workers, and an endless paper trail cannot cope with your demands and available personnel.

That’s where AMRs come in.

These small and intelligent vehicles weave between stations and move parts and finished products like invisible hands.

What makes AMRs so unique?

They sense, adapt, and optimize routes instantly, without human intervention. They rewrite internal logistics faster than you can say, “Where’s my pallet?”

Just like we’ve done with the trends above, let’s show you how AMRs drive change through a minor case study set up in a drink bottling plant.

Table 3. Before vs. After: Drink Bottling Plant Adopts AMRs for Internal Logistics.

Every missed pallet, every forklift accident, every labor delay. It all silently leaks cash. AMRs patch these leaks with precision, speed, and a lot fewer worries.

Fig. 3. Financial Impact of AMR Adoption at Drink Bottling Plant.

You can bring AMR technology to your factory floor with full-on customization and integration with your existing ERP and MES platforms.

Where to Find Robotics and AI Integration Services?

At Verdusco Automation, we do much more than talk about trends. We design, integrate, and maintain real-world solutions capable of rebuilding manufacturing from the ground up.

Our robotics and AI integration services are proven to help you:

➔ Connect every layer of your operation with precise designs.

➔ Complete integration projects from planning to installation.

➔ Improve uptime, safety, and employee satisfaction with smart layouts tailored for your factory floor.

Contact Verdusco Automation today!

📩 Get in touch now: https://www.verduscoautomation.com/contact.