3 Silent Ways Manual Material Handling Crushes You (And How to Fight Back)

You know the feeling. It’s 10:42 a.m., and already your warehouse floor is starting to look like a game of Tetris.

Workers zigzag around overloaded carts. Forklifts honk through tight aisles. Someone slipped a disc while lifting a 45-pound box for the fifth time today.

Orders will be late. The to-do list will keep growing longer and longer.

What you witness is the hidden chaos of manual material handling. It creeps in quietly—wasting hours, draining money, and exhausting your team. And while it might feel like “just how it’s always been,” the truth is, it’s tiring and consuming. But there’s a way to fight back.

This article from Verdusco Automation walks you through:

● What outdated processes are silently costing you

● How Automation in Warehousing is rewriting the rules, especially with Autonomous Mobile Robots (AMRs)

● Which industries are already winning big

● And where to start if you want to make the shift today

Manual Material Handling Chips Away at Your Business

The worst part? You might not even notice.

These are three sneaky ways manual material handling is putting you in hot water. Once you see them, you can finally fix them.

#1. Employee Fatigue and Injury

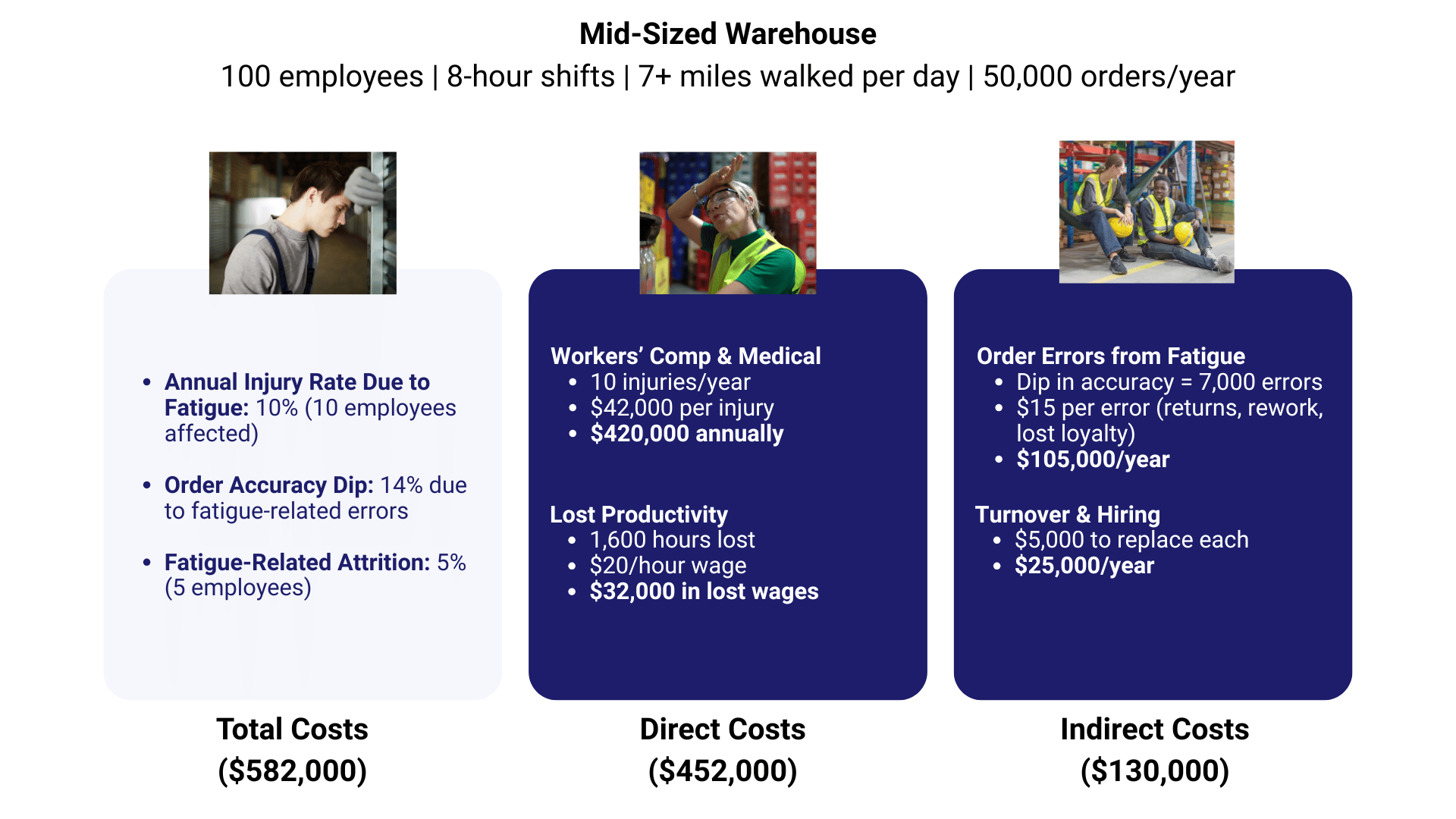

Marathoning across the warehouse. Moving boxes around. Lifting heavy loads. It’s all fun and games until the clock marks 2 pm. Then, fatigue spikes errors, dipping order accuracy, and the ongoing rhythm foments rising injuries, which over time turn into absenteeism.

Have you measured the financial impact of this scenario in your facility?

Let’s give you a hand by showing you how it might hurt a logistics operator processing 50,000 orders per year.

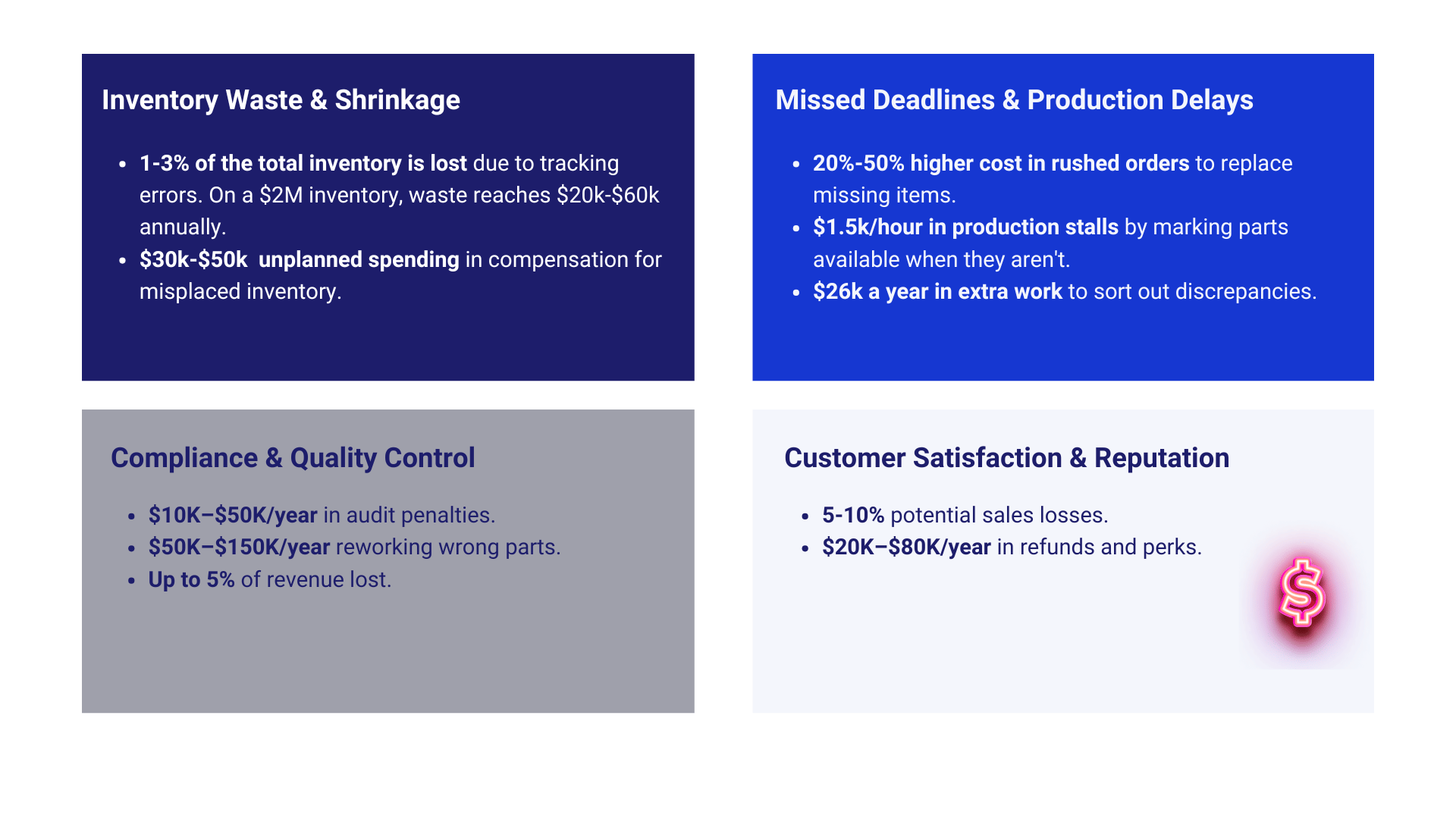

#2. Accuracy Blind Spots

Do you rely on manual tools and logbooks to track part movement? A single wrong entry can delay your motion and make you pay for it. How much so? Look at the quadrant figure below for clues.

Verdusco Automation motivates you to create your own quadrant. By putting a number next to missed deadlines, wasted inventory, and blame games, you can move forward and plan the next move.

#3. Poor Space Utilization

Manual material handling works hand in hand with human-accessible layouts—wider aisles, lower shelving, and scattered item storage for quick access.

Over time, the setup leads to cluttered zones, inefficient racking, and dead space.

Why It Hurts:

● Reduces overall storage capacity by up to 20–30%.

● Forces premature warehouse expansion or off-site storage fees, costing $50k–$150k annually.

● Increases pick times due to disorganized layouts.

Meet Your Golden Ticket to Painless Material Handling: Automation in Warehousing

Automation in warehousing opens a more efficient, profitable, and sustainable future for your logistics business. And at the forefront of this transformation are autonomous mobile robots (AMRs).

AMRs are smart, nimble, and ready to work.

With real-time mapping, route optimization, and safe human-machine collaboration, they can:

● Move goods efficiently across zones

● Adapt to changing floor layouts

● Integrate with your WMS or ERP

● Run 24/7 with minimal downtime

Cost-saving bonus?

Logistics facilities that implement robotics tend to see up to 30% labor cost savings and 20% productivity boosts within the first year.

Manufacturing, e-commerce, healthcare, and other industries are reaping the advantages of automation in warehousing.

Look at the stunning results some specific industries see after AMR deployment.

Food & Beverage

● Before: Workers manually hauled crates between deep freeze storage and dock doors, exposing themselves to fatigue and temperature risks.

● Solution: AMRs with thermal route planning and cold-chain integrity sensors.

● Results: 18% faster loading, 12% fewer accidents, and 5°F more stability across the cold chain.

Pharmaceutical

● Before: Manual handlers navigate tight aisles with delicate payloads. Breakage and misplacement are common.

● Solution: AMRs with dynamic shelving and smart payload tracking.

● Results: 22% fewer picking errors, faster QA clearance, and increased operator satisfaction.

Automotive

● Before: Workers push carts loaded with heavy components between assembly cells.

● Solution: A fleet of coordinated AMRs synched with takt time.

● Results: 30% improvement in part delivery speed, zero line stoppages from transport delays.

Integrate Autonomous Mobile Robots (AMRs)

Think your operation is too small or too chaotic to automate?

Verdusco Automation specializes in smart, affordable solutions that elevate your logistics without derailing your budget.

We offer:

● Custom AMR deployment & WMS integration

● Safety-first automation design & retrofit

● Continuous support & optimization.

The results? Higher uptime. Fewer injuries. Happier staff. Faster fulfillment. And a warehouse that runs smoother than ever.

Contact Verdusco Automation today!

📩 Get in touch now: https://www.verduscoautomation.com/contact