Predict. Prevent. Perform: SCADA and IIoT for Mission Ready Operations

Meet Matthew.

He’s the Maintenance Reliability Lead at a Tier-1 military-grade avionics component factory.

His CNC machines cut titanium for propulsion systems. When a spindle fails, it’s not just another late order. It’s a national defense setback. Naturally, his plant must run like a Swiss clock. Too often, it doesn’t.

Matthew’s tired of firefighting. He wants foresight, not hindsight.

That’s where SCADA (Supervisory Control and Data Acquisition) and IIoT (Industrial Internet of Things) step in. These automation tools monitor and predict what’s coming, empowering teams to spot trouble before it hits.

How does it all come together?

This Verdusco Automation article shows how manufacturers like Matthew can move from reactive chaos to mission-ready operations in the blink of an eye.

When Critical Operations Go Off the Rails

One morning, Matthew arrives to find that the vibration logs came too late. When a motor burns out mid-production, he barely has time to react.

The acrid smell of the overheated servo motor fills the floor. Frustrated, he explains to procurement how a “cost-saving” bearing just cost them $100,000. Meanwhile, operators demand quick action to get the line back up. And executives send an email with red figures everywhere. They want answers, and fast.

If his plant can’t afford a single misstep, Matthew knows it’s time to rethink the maintenance strategy.

Traditional Maintenance Practices vs. Predictive Maintenance

For years, Matthew has been stuck in one of two cycles: reactive or preventive maintenance. Reactive maintenance is a response to surprise call-offs. Preventive maintenance means replacing a motor at 10,000 hours only to find it was already failing at 8,000.

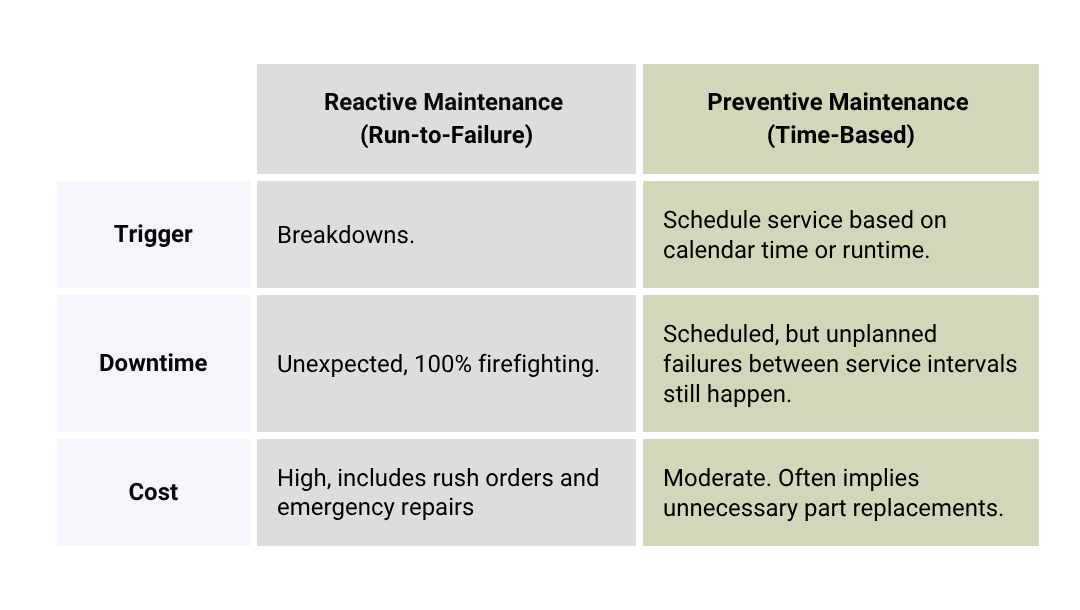

Both are liabilities. Here’s why:

Figure 1. The Problem with Old Maintenance Strategies (Source: Verdusco Automation).

The only way to break the cycle is to adopt a smarter maintenance strategy.

Predictive maintenance is that option. It empowers O&M teams to use real-time condition data to minimize downtime, reduce waste, and cut costs.

Let’s see how you can stop chasing breakdowns and start predicting them.

SCADA and IIoT: The Power Duo Behind Predictive Maintenance

Trading in unplanned breakdowns for 24/7 mission-ready operations is not magic. It’s data!

Matthew works with a high-precision 5-axis CNC mill, critical for machining avionics housing. Despite a strict preventive maintenance schedule, it’s a constant source of surprise failures.

With predictive maintenance, everything changes. SCADA pulls live data on pressures, temperatures, and vibrations. IIoT sensors enrich that data with deeper, faster insights. For Matthew, it’s like having eyes and ears on every asset.

Here’s a before-and-after recap for Matthew’s case.

Figure 2. Before and After Predictive Maintenance (Source: Verdusco Automation).

By modernizing the SCADA system and integrating IIoT vibration and temperature sensors onto the mill’s spindle and ball screws, Matthew:

Gets access to early warnings, fewer surprises, and treats anomalies before failure occurs.

Schedules replacement during a planned downtime, with the part already on the shelf.

Gains tactical automation armor to reduce machine downtime and extend equipment life.

Want to know what’s coming before it hits you?

Mission Ready Operations, No Excuses

Mission-ready operations are the standard when predictive tools back your team.

Verdusco Automation helps manufacturers like you move from firefighting to foresight with SCADA and IIoT-powered predictive maintenance.

We don’t overcomplicate. We design solutions that work, day in and day out.

Here’s how we support you:

➔ Integrated Automation Solutions. Tailored SCADA and IIoT platforms that deliver actionable insights, not noise.

➔ Industrial Automation Design. Smart system architecture that reduces downtime and maximizes asset life.

➔ Control Systems Engineering. Reliable control logic that ties your operations into one cohesive, predictable flow.

Our solutions mean safer plants, higher productivity, leaner costs, and employees free from constant firefighting.

Ready to step into reliability?

Contact Verdusco Automation today.