Cobot Compliance Made Clear, Fast, and Stress-Free

The minute the audit notice hits, your mind races:

Did we document the safety review when the cobot was moved from Assembly Line B to Packaging last month?

That simple relocation, done to boost efficiency, might have created a serious compliance gap.

In collaborative operations, any change in tooling, layout, speed, or human-robot spacing can trigger a new requirement under ISO 10218-2 or HRI (Human-Robot Interaction) safety standards. And if the risk assessment wasn’t updated, you’re exposed.

This Verdusco Automation article shows how automated compliance dashboards linked to SCADA push real-time risk assessment updates and validation logs straight to your screen.

No guesswork. No late-night cross-checking.

Just clean, updated proof at the pace your plant moves.

Your Base for Reliable Cobot Compliance: Making ISO 10218 & HRI Standards Clear

ISO 10218 looks intimidating, but once you break it down, the fog lifts:

ISO 10218-1 is the cobot manufacturer’s responsibility: Ensuring the cobot has built-in safety functions, such as Safe Torque Off, power-and-force-limiting capability, and safe motion features.

ISO 10218-2 is your world (along with the integrators): You must prove the cell is safe. The standard governs the entire application (the robot + end-effector + workpiece + layout + human interaction).

Then come the HRI standards (ISO/TS 15066 is the most referenced):

They define speed limits, force thresholds, spacing rules, and safety verifications on the cobot side when a person enters the work envelope.

ISO 10218 and HRI standards make cobot compliance come full circle.

The moment you change something in the cell (e.g., different table height, adjusting a path, or adding a new part) without refreshing the risk assessment, a non-compliance may arise. This situation happens all too often because production decisions move faster than quality documentation ever will. Thus, most teams stumble during a cobot compliance audit.

From Paper Piles to Digital Proof: Speed Up Plant Safety Documentation

Most audit stress doesn’t come from cobots. It comes from the documents behind them.

When plant safety documentation lives in binders, email threads, and improvised spreadsheets, every audit becomes a scramble.

Digital compliance dashboards solve this immediately. You get real-time, timestamped logs that validate themselves as operators work. No blind spots. No “missing page 7 of the risk file.” Just a clear glow of updated proof that refreshes every time a condition changes.

You’re not chasing evidence anymore. It’s already there.

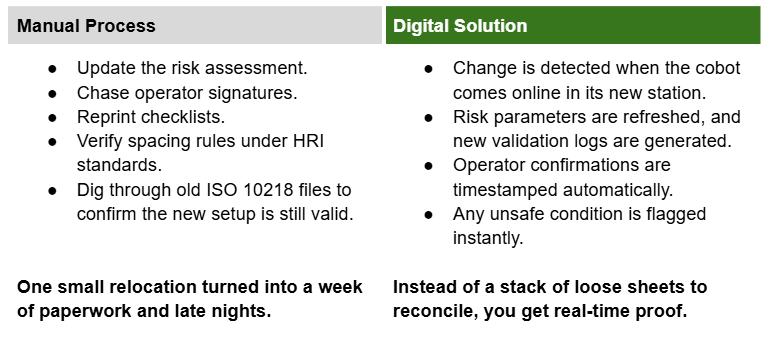

Take our previous example: Production decided to move a cobot from Assembly Line B to Packaging last month.

The scavenger hunt stops, and your cobot operations stay audit-ready without the paper chase.

ROI You Can Measure in Hours and Dollars

Manual plant safety documentation drains you and invites errors when something slips through the cracks. Automated logs prevent that.

Here’s what manufacturers typically gain:

40–60% less labor spent on audit prep.

Fewer compliance failures thanks to continuous proof.

Near-zero documentation-related downtime across production lines.

Faster corrective actions because issues are flagged automatically

And yes, less stress.

You finally stop holding your breath every time an audit is announced.

3 Steps to Ensure Your Cobots Are Audit‑Ready

Automated dashboards solve the hardest part of cobot compliance: keeping ISO 10218 and HRI proof updated without the grind of manual re-audits. They turn a once-fragile system into a steady, reliable routine.

Here’s how Verdusco Automation helps you get there:

SCADA Programming for Real-Time Safety Insight

We connect your cobots, sensors, and safety functions into a single view that updates instantly.Industrial Automation Design That Reduces Risk

We design and validate applications, so your robot, end-effector, and environment stay aligned with ISO 10218-2 and HRI requirements.Integrated Automation Solutions That Scale with You

From single cells to full-line upgrades, we build solutions that raise safety, increase productivity, and reduce the physical strain on your team.

You get clearer days. Easier audits. A plant that feels lighter to run.

Start the conversation: Contact Verdusco Automation today!

📩: https://www.verduscoautomation.com/contact

****

Final Note: This article illustrates what is achievable. A custom analysis of your specific facility is required to calculate your precise ROI and project timeline.