Burnout Teams, Rising Costs? Automated Night Shifts Fix Both

Night shifts are a painful necessity for many manufacturing plants. But let’s be honest, it comes at a high cost: morale dips, errors rise, and turnover spikes.

Human bodies aren’t wired for nocturnal labor. Studies show that night workers suffer higher risks of chronic fatigue, weakened immunity, and even long-term health issues. Daytime sleep? It’s a poor substitute for the deep, restorative rest our brains demand under the cover of darkness.

What can you do?

In this article, Verdusco Automation shows you how automated night shifts powered by smart automation and robotics can take over the dreaded graveyard shift to make your operations run smoothly, without ballooning costs or sacrificing safety, quality, and employee well-being.

The Real Cost of Pushing Through the Night

It’s your kid’s school play. The lights dim, the curtain lifts… But you’re not there. Instead of clapping in the audience, you’re clocking in for the night shift. Same story on Christmas Eve. New Year’s. Your anniversary. While the world sleeps or celebrates, you’re suiting up for the grind.

You tell yourself it’s just part of the job. But over time, it wears you down. It wears everyone down. You are not tired in your bones but in your spirit.

For the company, the price is also steep:

Higher turnover.

Slower responses to issues.

Lower energy across teams.

More mistakes, more waste, more rework.

How much longer can you afford this model?

Enter Automated Night Shifts: Keep the Lights On While Your Team Sleeps

Now imagine showing up at 8 AM, energized and clear-headed, because your plant ran overnight without you. No fire drills. No frantic texts. Just a clean, safe, and productive handoff.

That’s the promise of smart automation.

Robotics and intelligent systems don’t just plug holes in your schedule. They transform how your factory performs. Here’s how:

1. Uninterrupted Operations

Autonomous Mobile Robots (AMRs)

Like CabraMove’s AMRs, these self-navigating carriers transport materials flawlessly, 24/7, without breaks or burnout.

● SCADA & DCS systems

Check and act on production lines remotely, with real-time alerts if anomalies arise.

2. Predictive Maintenance (No More 4 AM Fire Drills!)

IoT Sensors

Smart sensors flag wear and tear before it spirals into failure. That $50K conveyor meltdown? Dodged—because the system pinged you at 5 PM, not 5 AM.

3. Traceability & Safety (Even in the Dark)

Automated Workflows

Barcode scanners, robotic arms, and AGVs handle repetitive tasks with surgical precision. No human error. No second-guessing. Just flawless consistency, shift after shift.

ROI You Can Feel (and Measure)

Let’s compare two scenarios:

BEFORE: A fully staffed night shift team covering 10 PM to 6 AM.

AFTER: A smart automation system with robotics handling the night load.

The setting is a cement manufacturing plant with a capacity of 1 million metric tons. Here are the results:

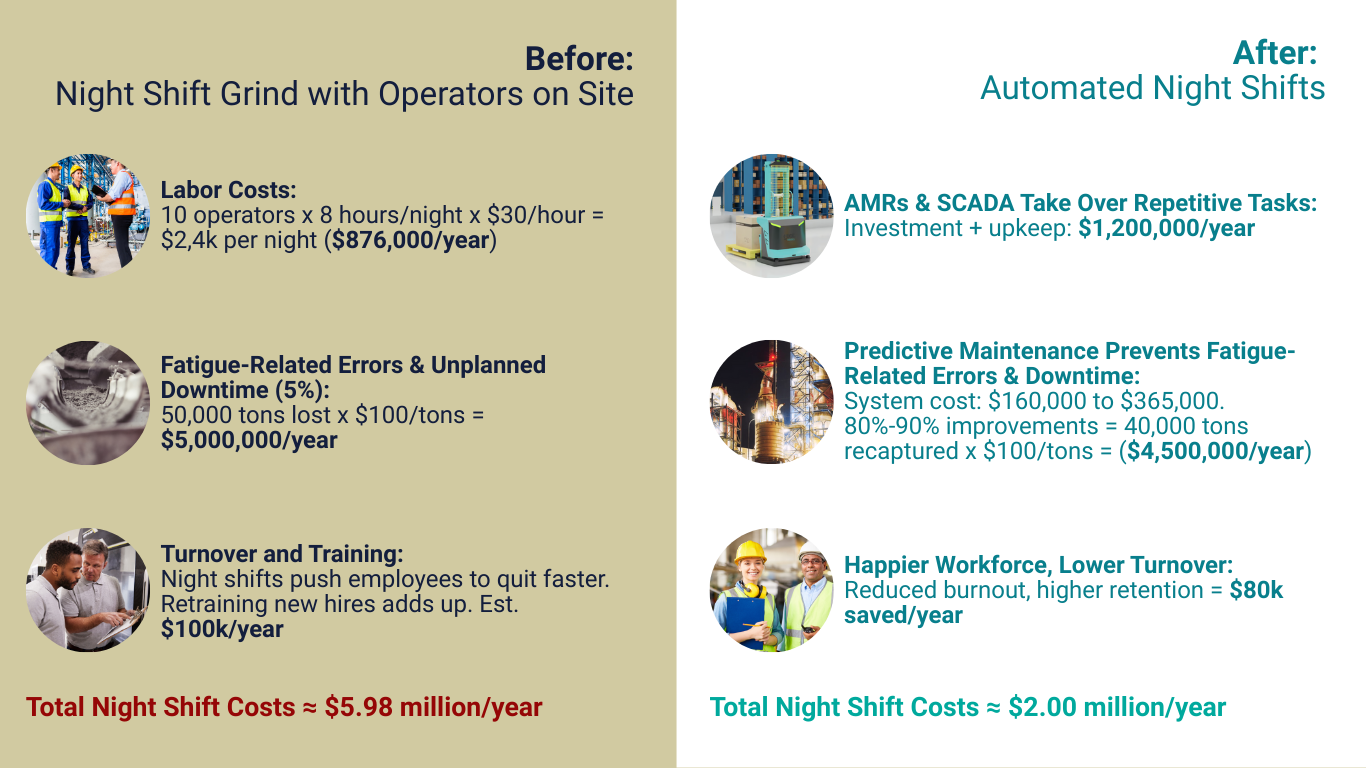

Figure 1. Manual Graveyard Shifts vs. Automated Night Shifts (source: Verdusco Automation).

Figure 1 presents early-stage approximations that can help you frame your opportunities. Just remember: Every facility is different. Layout, labor structure, product flow, and existing infrastructure. It all matters.

Your Move: Where to Start If You’re Ready for Automated Night Shifts

Smart automation systems aren’t just workhorses. They’re watchdogs.

Every component, from robotic pickers to control cabinets, comes with layered cybersecurity protocols, access control, and traceable logs.

Beyond automating tasks, you’re building a secure, auditable system that works even when no one’s on-site.

The result? More uptime. Fewer accidents. And peace of mind at all hours.

Verdusco Automation helps manufacturers like you embrace automation without the overwhelm.

Start with any of these services:

➔ Integrated SCADA & Control System Design: 24/7 visibility and control.

➔ Autonomous Mobile Robot (AMR) Deployment: your tireless night crew.

➔ Predictive Maintenance and IoT Integration: prevent costly failure surprises.

Contact us today to book a consultation and build the future of your plant, one smart move at a time.