Why Centralized Process Control Is the Shortcut to Clean Operations

Production reports a delay.

Sales is pinging you for forecasts.

Maintenance says a line is down.

As you search for the truth, you scroll through five Excel files, trying to decode conflicting numbers. Meanwhile, the walkie-talkies cut off mid-sentence during a critical update.

Your systems were built for yesterday. And now you’re paying the price.

So, how do you protect your team—and yourself—with visibility, traceability, and clarity?

In this Verdusco Automation article, we’ll show you why centralized process control is a solution to your crisis. You’ll see why it is a solid strategy for digital transformation in manufacturing today, saving hours (and big bucks) daily.

Let’s dig in.

Painful Plant Problems That Centralization Fixes Fast

In manufacturing, even a minor disconnect between departments can cause ripple effects that drain productivity and budgets. Centralized process control (CPC) bridges these gaps with synchronized, real-time data. No more second-guessing. No more silos.

When your data is lean, live, and visible, everyone acts on time:

CEOs zoom out to see trends across the plant.

Operators monitor equipment status in real time.

Maintenance teams catch issues before they escalate.

But what does that actually look like?

Let’s show you.

We'll use a mid-sized paint manufacturing company (with a production capacity of 1 million metric tons) as an example of what centralized visibility can fix—fast.

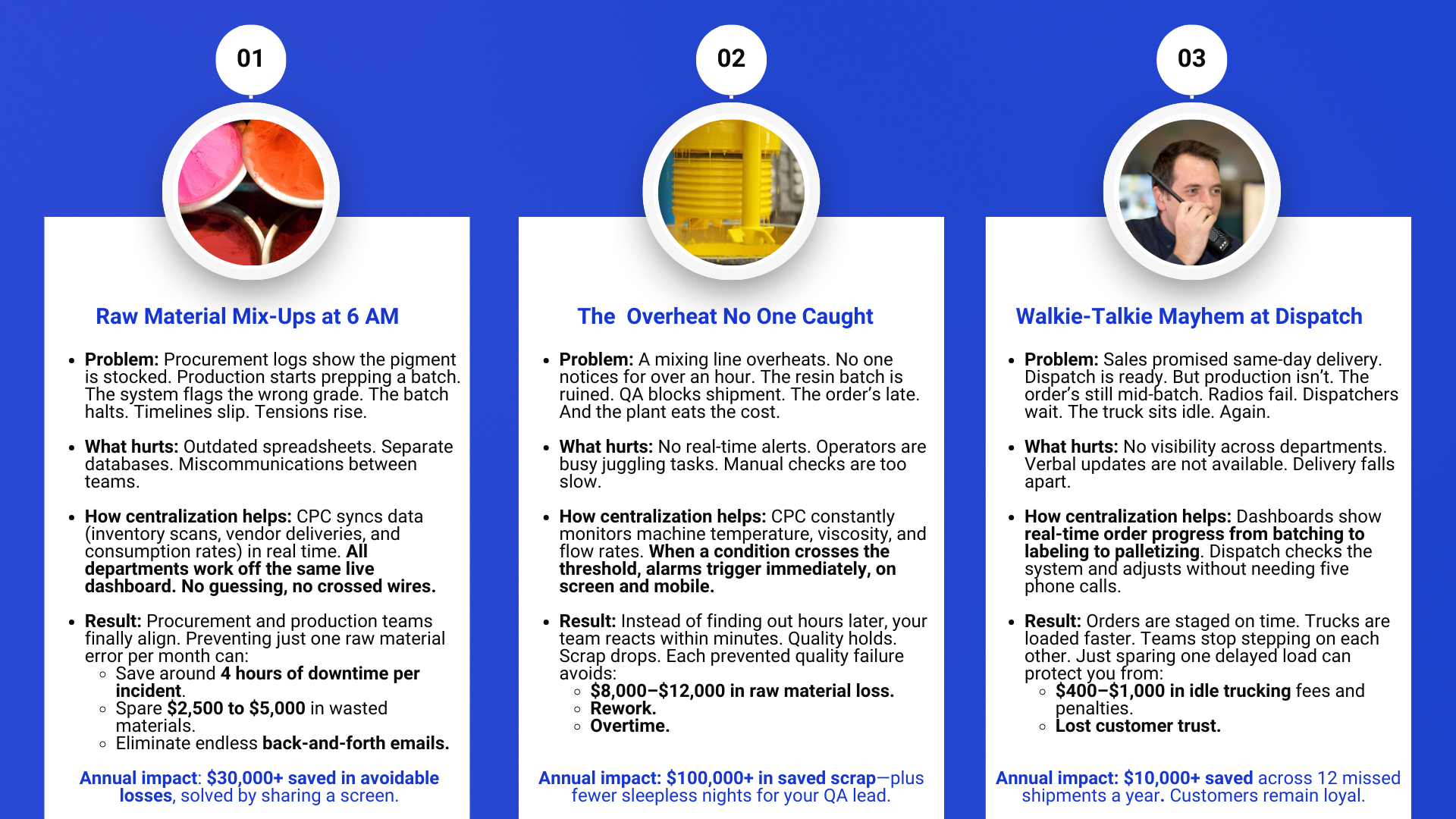

Figure 1. Three Pain Points Solved with One Smart Solution: Centralized Process Control (source: Verdusco Automation).

In summary, centralized process control offers you:

➔ One screen, total control.

➔ Instant insights, instant action.

➔ Less noise, more flow.

Metrics Your CFO Cannot Ignore

At Verdusco Automation, we’ve seen what centralized process control can unlock when it’s tailored to the real-world conditions of your plant.

Based on our experience working with manufacturing clients across several manufacturing sectors, companies may reach:

➔ +20% Maintenance Efficiency: Predictive alerts and scheduled downtime reduce breakdowns and extend equipment lifespan.

➔ -30% in Time Spent on Manual Reports: Real-time dashboards eliminate the need for spreadsheets and siloed updates.

➔ +15% Productivity Gains in Year One: Fast feedback loops help operators catch and fix issues before they escalate.

But let’s be clear: These are Class V estimates. The actual impact depends on your industry, production capacity, infrastructure, team structure, and level of digital readiness. To know what’s truly possible for your operation, a full assessment is key.

Verdusco Automation is ready to support you. We’ll help evaluate your current systems and build a scalable, realistic roadmap—step by step.

Digital Transformation in Manufacturing: Ready to Lead, Not Chase?

We get it. Upgrading isn’t just a technical hurdle—it’s an emotional one, too. The investment feels big. The disruption feels risky. But here’s what comes after:

A calmer floor.

More productive shifts.

A team that’s aligned and empowered.

At Verdusco Automation, we build solutions that meet you where you are—and help you grow from there:

Ignition®: A powerful centralized automation platform for scalable control and real-time data dashboards.

Integrated Automation Design: Custom system design that connects seamlessly with your infrastructure.

Autonomous Mobile Robots (CabraMove): Smarter internal logistics that take strain off your people.

These aren’t “fancy extras.”

They’re modern tools for factories that want to compete, save, and lead.

Digital transformation in manufacturing should be approachable, achievable, and empowering. With Verdusco Automation, it is.

Contact us today!