Late Deliveries? Your Team Isn’t the Problem—This Is

Every day starts strong. Every unit is on track. Orders are lined up. But somewhere in between, the rhythm stumbles. And once again, your perfectly planned schedule slips behind.

If you’re in charge of operations or logistics at a manufacturing plant, chances are you’ve felt this weight. The pressure to meet delivery windows. The frustration of not knowing where the holdup is. And worse, being tempted to blame it on the team when they’re already stretched thin.

In this article, Verdusco Automation breaks down what’s really slowing you down and how to fix it in under 90 days. We’ll explore a proven path forward: Autonomous mobile robots (AMRs) and smart routing logistics.

The Reason You Are Always Running Behind Schedule

When things go sour—missed shipments, incomplete assemblies, sudden downtime—it’s easy to look at the team.

But take a closer look.

They’re not jeopardizing your operations. They’re overwhelmed. Because the system they rely on wasn’t built for the speed, volume, or complexity of today’s manufacturing.

Manual routing. Guesswork logistics. Verbal instructions. Sticky notes. It’s all a breeding ground for mistakes. And each small misstep snowballs, turning into:

Late shipments

Disrupted production

Employee burnout

Customer complaints

Blaming people, instead of processes, is expensive. Not just in morale, but in money.

Pay attention to the hidden source of bottlenecks. They are everywhere!

A part in the wrong aisle. A forklift waiting for a clear path. A missed alert for an urgent delivery. You don’t see them in reports, but you feel them every day.

Rethink Internal Logistics with Autonomous Mobile Robots (AMRs) and Smart Routing

Take a hard look at your current logistics strategy:

Is it still running on whiteboards, radio calls, and gut instincts, with traceability, dynamic routing, and accountability nowhere to be found?

Are your operators stuck backtracking for parts, babysitting pallets, or abandoning critical tasks just to cover last-minute fire drills?

Are you deliberately slowing down just to stay in control, leaning on forklifts for precision and coordination they were never built to handle?

By today’s standards, that’s not a logistics strategy. It’s a patchwork. And patchworks tear under pressure.

How can you move beyond the “good enough to get by” area and finally gain precision, consistency, and visibility?

This is where Autonomous Mobile Robots (AMRs) and smart routing logistics step in. Not as a gimmick, but as a tactical upgrade.

What AMRs and Smart Routing Bring to the Floor

AMRs and smart routes strip the guesswork from internal deliveries, bringing order and clarity in 3 powerful ways:

➔ Movement with purpose. AMRs haul loads with smart navigation tools. They adapt routes in real time, respond to floor conditions instantly, and flow around bottlenecks.

➔ Full tracking, zero guesswork. No more hunting for missing parts or relying on hallway updates. Every move is visible, timestamped, and traceable.

➔ Built-in task prioritization. Smart routing systems automatically rank, reroute, and assign tasks based on urgency and efficiency.

You are in control without micromanaging every pallet. And, while the system handles movement, your team stays focused on what actually moves the needle.

Bonus?

No programming background required.

On-the-fly training is doable.

Integration is fast and low-disruption.

You’re not just automating movement. You’re installing a logistics brain that learns and adapts without weighing down your team.

What Happens When You Replace Outdated Routines with Intelligent Movement?

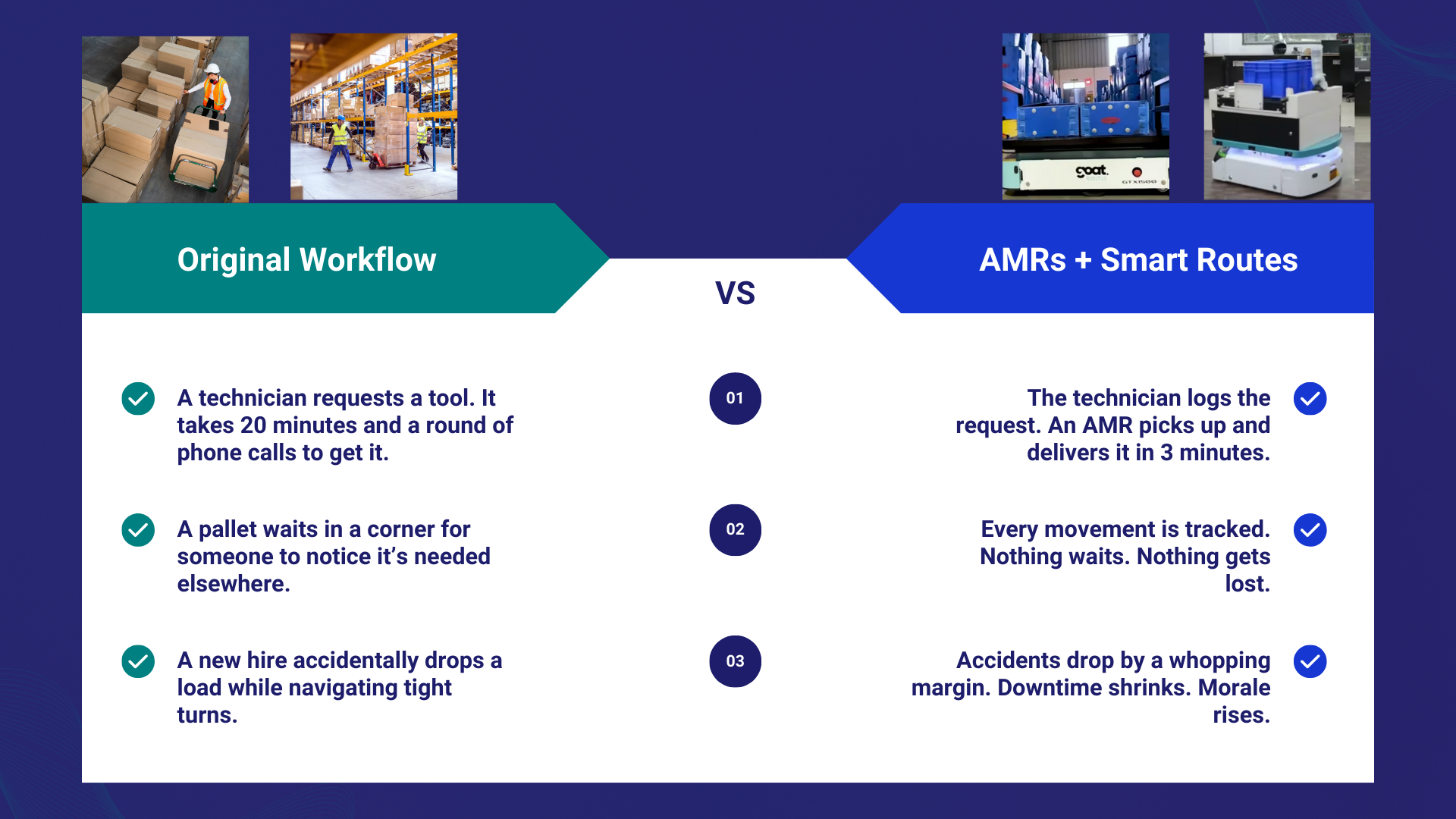

Traditional workflows, built around forklifts and reactive decisions, fall short under pressure. Delays stack. Communication gaps grow. Errors sneak in. In contrast, Autonomous Mobile Robots (AMRs) with smart routing offer speed without the scramble, accuracy without oversight, and coordination without chaos. Just take a look:

Figure 1. How AMRs+ Smart Routes Transform Logistics (source: Verdusco Automation).

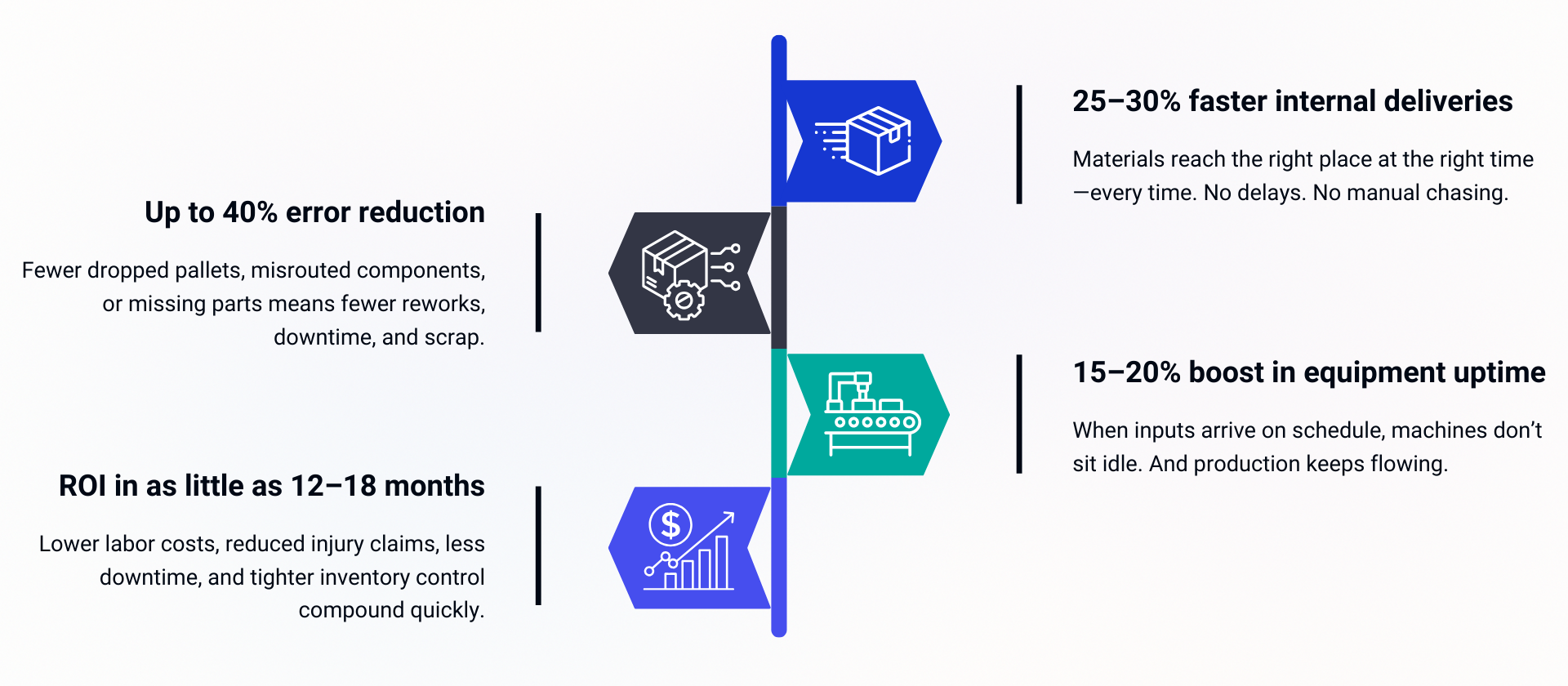

ROI Snapshot: The Payoff of Smarter Movement

Still on the fence? Let’s talk numbers.

Companies that invest in Autonomous Mobile Robots (AMRs) and smart routing logistics aren’t chasing hype. They’re locking in tangible gains that show up fast on the balance sheet.

Based on Verdusco Automation’s experience with clients, you can gain:

Figure 2. Operational ROI at a Glance (source: Verdusco Automation).

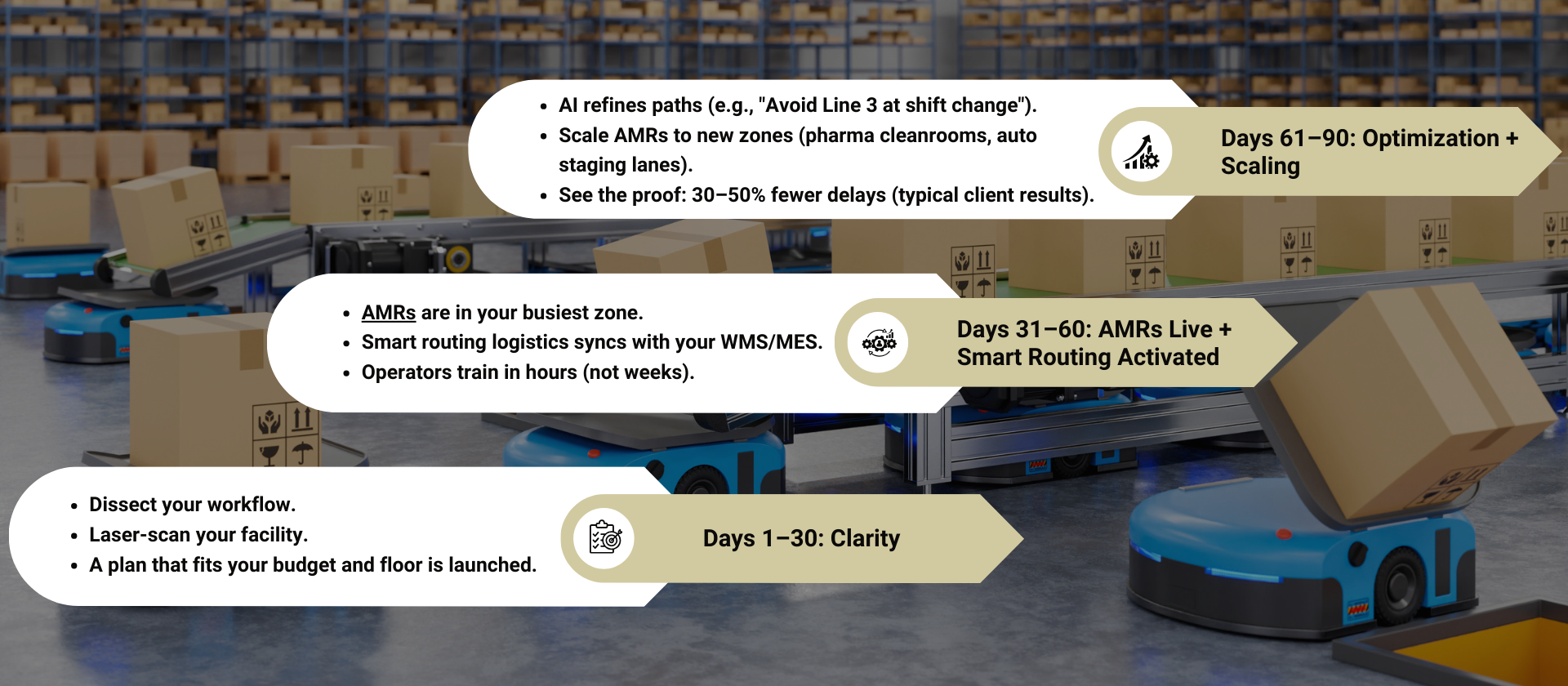

Ditch Delays in 90 Days

Automation upgrades don’t have to be long-winded, disruptive, or risky. With Verdusco Automation, your journey from logistics headaches to streamlined, smart operations can be done in as little as 90 days, without tearing up your floor or draining your team.

Figure 3. AMR Rollout Timeline (source: Verdusco Automation).

Here’s how we help:

Autonomous Mobile Robots: Compact, powerful, and fleet-friendly.

Smart Routing Design and Simulation: Plan before you commit. See how routing will improve.

Custom Control System Integration: Make everything work together seamlessly.

Build a future where nothing sits idle, no part goes missing, and every worker feels safe and empowered.

Contact Verdusco Automation today!

📩: https://www.verduscoautomation.com/contact