How to Modernize Your Production Line—No Shutdown Required

Upgrades sound great on paper—until someone says you need to stop the line.

That’s where most operations managers flinch. They know even a slight pause is a gamble. It brings lost revenue, late deliveries, frustrated clients, and anxious staff.

So, when the “modernize production line” talk comes up, the fear is real. Managers wonder, “Can we afford to stop?” and “Is it really worth the risk?”

Here’s the truth: You no longer have to halt production to modernize.

This Verdusco Automation article walks you through how smart manufacturers are updating their lines in real-time. You’ll see what tools make it possible, what steps teams are using to pull it off, and what kind of ROI is actually on the table.

Let’s put the shutdown myth to bed.

Why You Don’t Need to Go Dark to Go Smart

Manufacturers often think of upgrading as weeks of downtime, lost output, and frustrated teams. A while ago, that might have been the case. But now you can totally flip the switch without killing the lights.

For starters:

➔ Upgrades don’t have to be all-or-nothing. They allow layer-by-layer integration.

➔ AI-driven robotics and modular controls enable continuous production during transitions.

➔ Live upgrades spare revenue loss, workforce disruptions, and panic.

The steps to engage in intelligent integration, instead of brute-force replacement, involve precision, planning, and leveraging the right technologies.

Meet the Tools to Upgrade on the Fly

Today’s smart tools aren’t bulldozers. They’re building blocks.

Let’s break down the tech that keeps your floor moving while your systems evolve.

Modular Controls for Process Continuity

Instead of ripping out legacy systems, inserting “plug-and-play” pieces into specific parts of your process ensures seamless automation without interruptions.

For a food processing plant, this might mean upgrading a specific mixing tank’s controls to improve consistency without stopping the entire pasteurization line.

The investment range can go from $20k to $150k (depending on system size). Benefits include reduced process variability, improved throughput, fewer manual errors, and, best of all, zero downtime during installation. No agonizing lost revenue related to a complete blackout exists.

AMRs for 24/7 Mobility

Autonomous Mobile Robots (AMRs), like those from CabraMove, keep materials moving while upgrades happen, preventing bottlenecks and maintaining workflow efficiency.

They don’t take breaks, don’t get sick, and never stop your line. You drop them in, map the route, and let them work. While operators stay focused on high-value tasks, AMRs handle the grunt work.

The investment range goes from $40k to $200k per unit. Labor savings, fewer forklift accidents, and continuous material flow even on skeleton crews figure in the expected ROI.

PLCs and SCADA for Smooth-as-Silk Retrofits

Programmable logic controllers (PLCs) and SCADA systems can be installed as new layers on top of your existing hardware. Everything else keeps running. Think of it like updating your software while you’re still browsing the web.

Depending on the project, the investment range goes from $30k to $250k. The expected ROI features predictive maintenance, fewer stops, and real-time visibility. All while staying online.

The Step-by-Step Plan Smart Ops Teams Use

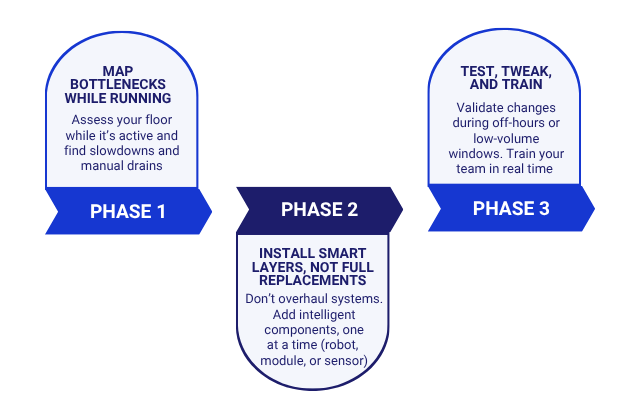

Smart ops teams go through this journey, ensuring every step keeps the production heartbeat strong.

This is their phased approach to avoid chaos and keep things moving:

Fig. 1. Phased approach used by smart ops teams in production lines to automate without downtime.

What Happens After the Upgrade: Real Results from Manufacturers Who Refused to Stop

They said it couldn’t be done, that modernization demanded a costly pause. But these manufacturers proved them wrong, emerging stronger and more profitable.

➔ Manufacturer reclaims 8-hour shift. An automotive manufacturer decided to update their robotic arm’s motion (in the production line), using optimized path programming and enhanced software algorithms. They saw time savings above 18%, $500k savings per year, and a 3-month ROI. No production line shutdown required.

➔ A snack plant boosted OEE with zero downtime. A company in the food and beverage space integrated modular batching controls and AMRs. The upgrades were completed during 2nd and 3rd shifts, with no impact on packaging or logistics. The result? OEE up 23%, labor costs down 18%.

Is Your Plant Ready for a Live Upgrade?

Do you rely on too many manual steps just to meet daily output? Are you seeing slowdowns but can’t afford to pause for inspection? Is your top talent stuck doing repetitive work, not high-value tasks?

If the answer’s YES, the time to automate without downtime is NOW!

But don’t run and Google “modernize production line” just yet. Instead, reach out to us, Verdusco Automation. We build trust with savvy, affordable solutions tailored to your size and industry. Our key services include:

➔ Integrated Automation Solutions

➔ Industrial Automation Design

➔ Control Systems for Industrial Automation

Who should NOT attempt a live modernization?

➔ Manufacturers with unstable legacy systems that require full replacements.

➔ Operations with severe inefficiencies that need foundational restructuring.

➔ Teams running severely outdated infrastructure with major safety concerns.

For them, a full audit is best. In that case, Verdusco Automation can help you plan a safe, phased transition.

Because tomorrow’s winners won’t be the ones who paused. They’ll be the ones who modernized in motion.

Contact Verdusco Automation today!

📩 Get in touch now: https://www.verduscoautomation.com/contact