How Military and Defense Automation Solutions Are Changing the Battlefield Game

As global tensions grow and supply chains get more fragile, defense suppliers feel the pressure to deliver. Yet, military factories keep losing precious hours chasing missing inventory and watching assembly lines halt due to late material deliveries.

The risk of falling behind is too huge to handle. So, modernization is the latest mission to accomplish. The question is not if but how.

This Verdusco Automation article is a guide to that mission.

We’ll break down why military and defense automation solutions change the field. From autonomous mobile robots military teams already trust to intuitive smart controls, the tools exist, and their results speak volumes.

Let’s unpack the challenge, the technology, and the transformation that’s already underway.

Military’s Hidden Struggles: Logistics and Efficiency

Steel shelves groaning under scattered components. Forklifts zigzagging across a tight floor. Operators walking miles a day—some hauling carts, others scanning inventory tags by hand.

Mid-sized military manufacturers can sure relate to that picture. They identify their spaces. Always impregnated with life-sucking effort instead of efficiency. All victims of the analog whiteboards, the verbal instructions, and the isolated spreadsheets of legacy systems.

When legacy systems and manual practices dominate:

Miscommunications flare.

Minor miscounts delay the entire production batch.

Operators burn out.

And supervisors lose visibility.

Yet the demand to increase speed, quality, and quotas never ceases.

Can you relate?

In an industry where timing and precision matter, even a 1% loss becomes a critical liability.

Automation is here to help you strengthen the areas where real power lies.

How to Turn the Tide

The global military robotics market is expected to surpass $30 billion by 2030. The biggest drivers? The need for precision, safety, and operational speed.

These ginormous numbers aren’t just for big players.

Automation is now more accessible than ever for small- and mid-sized defense contractors, especially with integration partners like Verdusco Automation.

Let’s show you how you can leverage the tech and benefit.

Meet AMRs: The Military’s Newest Recruits

Still pushing carts across wide facilities? How about inventory? Do you handle it manually, cross-checking lists the old-fashioned way? How’s that working out for you? Does it create fatigue and more errors? Does time slip away like water in your hands?

You got a choice!

Autonomous mobile robots (AMRs) for military services are here, now, and working hard. Use cases include:

Inventory management for real-time data capture and fewer errors.

Surveillance through constant patrolling (zero strains added to your teams).

Faster movement of goods across plants, depots, or facilities.

See the potential for yourself:

Table 1. Pain points in manual ops vs. gains with AMR solutions for the military and defense sector (source: Verdusco Automation).

Robots like CabraMove’s AMRs navigate complex layouts, adapt to obstacles, and ensure materials arrive exactly where and when they’re needed. No coffee breaks. No sick days. Just consistent uptime and precision.

The result? Happier employees, fewer injuries, and a visible boost in productivity.

Clients often report ROI within months. Not years.

Smart Controls: The Brain Behind the Operation

If AMRs are your feet, smart controls are your brain.

When PLC panels and operational accessories work in isolation, you get manual override processes stitched together with patches and hope. Diagnosing an issue could take hours, even days.

Every high-performing military facility can benefit from a smart control platform that does the thinking, coordinating, and optimizing. Without it, even the best equipment runs blind.

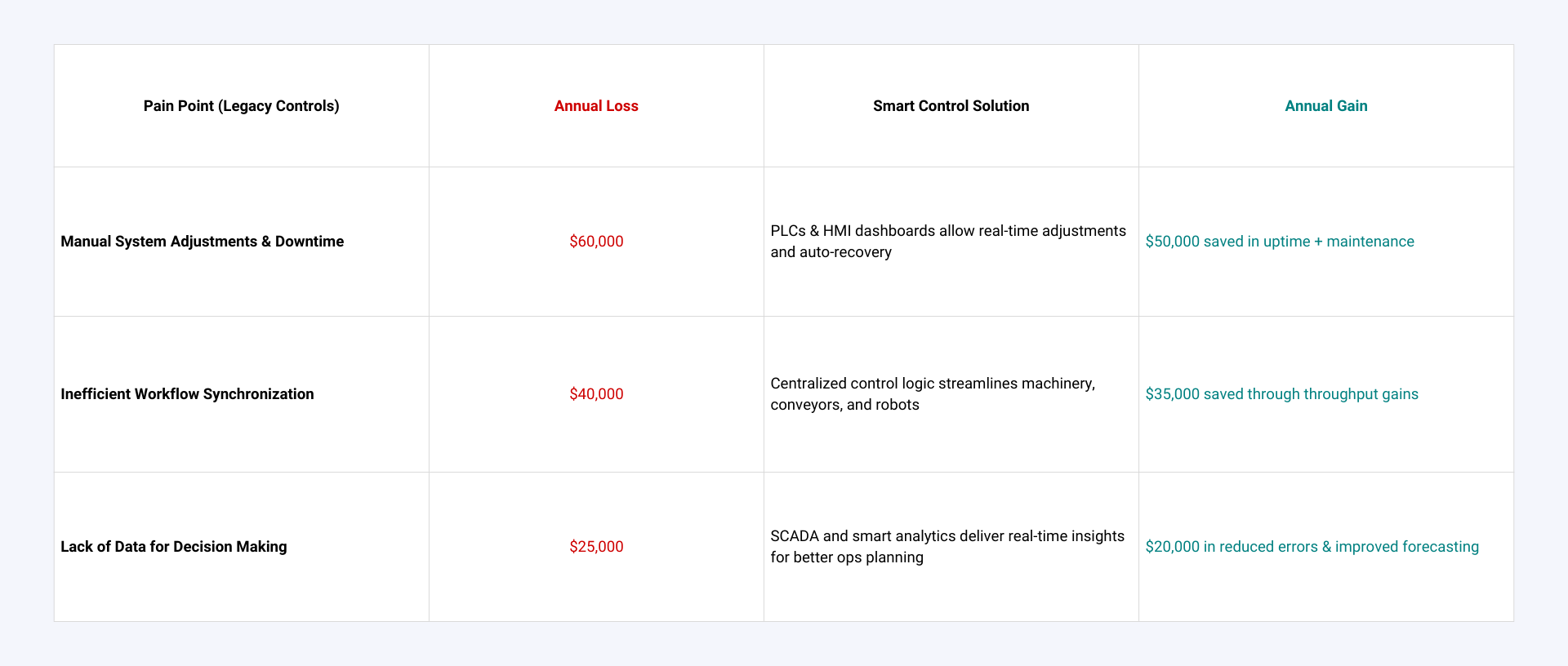

Here’s how legacy control systems quietly bleed your budget and how upgrading to modern controls turns losses into lasting gains:

Table 2. Pain points with legacy systems vs. gains with smart control solutions for the military and defense sector (source: Verdusco Automation).

Smart control platforms unify every moving part—machines, sensors, robots—into one real-time dashboard. Supervisors can monitor, adjust, and optimize on the fly. Predictive alerts prevent downtime. Remote access tools mean fewer boots on the ground are needed to solve issues.

Control no longer rests in silos. It becomes a command center of clarity.

The Future of Military Automation

We know that stepping into automation can feel like stepping into the unknown. That’s why Verdusco Automation works side-by-side with clients to design solutions that are practical, affordable, and transformational.

Our automation solutions are designed not just to reduce errors or save time, but to empower the teams who operate them—to help them become leaders of the digital era.

Three ways Verdusco Automation leads the charge:

Integrated Automation Solutions

We design systems that connect every part of your operation—from conveyors to control rooms—ensuring streamlined workflows.Autonomous Mobile Robots (AMRs) Implementation

We tailor robot deployments to your space, with custom mapping and support, so you start seeing ROI fast.Smart Control System Design and Integration

We install and optimize your digital command center so you get full visibility and control across your plant or facility.

We believe that your team already has what it takes. Automation just gives them sharper tools to work with. Let’s help your operators become supervisors of a smarter system.

Contact Verdusco Automation today!

📩 Get in touch now: https://www.verduscoautomation.com/contact