From Operator to Robot Supervisor: Why That’s a Win for Your Team

“My whole life I’ve torqued this piece. What do you mean a robot will do it now and I should oversee it?”

In the world of manufacturing, change is rarely easy. Years of experience are tied to routines, tools, and know-how passed down like family recipes. A shift feels personal, almost like losing a part of your identity.

But just like the leap from analog to digital, from paper logs to ERP systems, evolution in the factory is part of survival. Those who adapt thrive. Those who hesitate risk falling behind in a market that now runs on uptime, data, and precision.

The good news? You don’t have to lose your edge—you just have to sharpen it differently.

This Verdusco Automation article breaks down why shifting from operator to robot supervisor is not a downgrade but an upgrade. It’s about reclaiming energy, leveling up skills, and seeing smart automation as an ally in the modern production line.

The Operator’s Role Is Always Evolving

In the 1960s, before computers became mainstream, NASA depended on human calculators—people who ran complex math by hand. Fast-forward, and those same brains were soon learning how to work with computers, then how to build and repair them.

Today, we stand at another turning point. Robots, machine learning, and artificial intelligence are here to reshape jobs.

Instead of pressing buttons or lifting heavy loads, operators now have the chance to supervise high-tech systems, spot anomalies, and fine-tune processes with a deeper understanding of technology.

That doesn’t mean everyone is expected to become a coder overnight. It means human resources departments and leadership teams must actively reskill their staff.

At Verdusco Automation, we’ve seen it firsthand. The most successful automation projects are those where people evolve alongside the machines.

That’s how you build a future-ready workforce.

So, What Does a Robot Supervisor Actually Do?

Think of it as moving from manual to managerial. Instead of pushing, pulling, and aligning by hand, supervisors monitor, adjust, and lead fleets of machines. For instance, when working with Autonomous Mobile Robots (AMRs) like the CabraMove units we integrate.

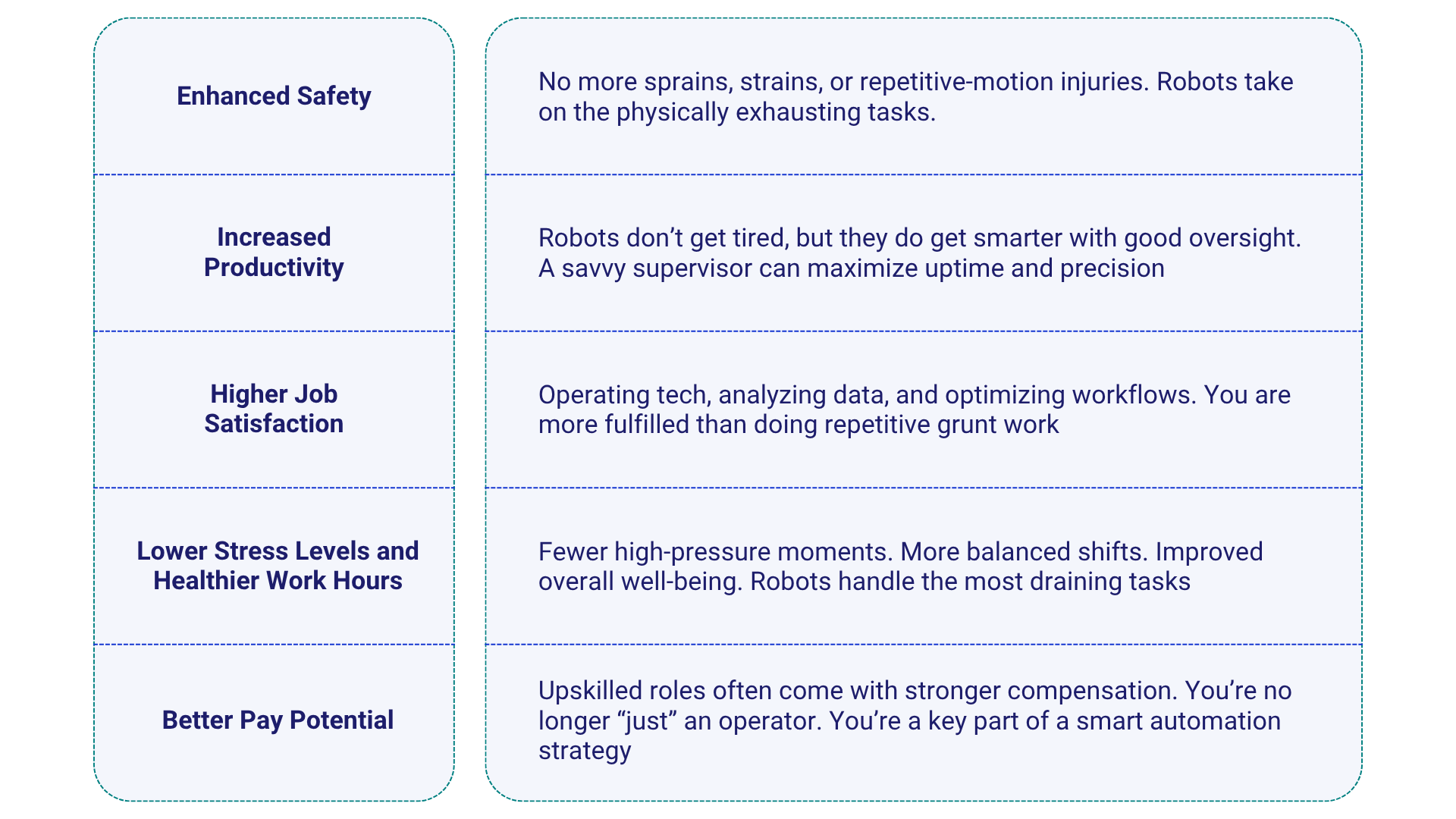

Here are the big wins from the transition:

A report by Deloitte found that manufacturers who invest in reskilling and smart automation see up to 20% efficiency gains.

It’s not just about the machines. It’s about what people become when the machines take the strain.

Future Outlook

“Change is the law of life. And those who look only to the past or present are certain to miss the future.” —John F. Kennedy.

The road to transformation doesn’t end once the robots roll in. That’s just the beginning. As your team shifts from hands-on operators to strategic supervisors, new challenges and opportunities will surface.

Will your staff feel confident navigating these technologies? Will your systems adapt to demand spikes and evolving processes?

Keep tabs with an eye on:

Emerging Technologies on the Horizon

Cobots (collaborative robots), digital twins, and AI-powered AMRs are already reshaping workflows. The factories of tomorrow will rely on systems that talk to each other, move autonomously, and learn from data. Supervisors who can interact with these technologies will become indispensable.

Preparing for Continuous Improvement

Supervision isn’t static. It’s an ongoing process of improvement. When operators shift their mindset from doing to optimizing, the floor becomes a dynamic lab for excellence. Your people aren’t just reacting. They’re thinking ahead, adjusting in real time, and delivering results that matter.

Finding a Trustworthy Partner

At Verdusco Automation, we help manufacturers transition with confidence. Our custom-designed automation systems are practical, affordable, and powerful enough to meet the needs of small- to mid-sized companies. And established large-sized titans too.

Here are three ways we support your journey:

AMR Integration with CabraMove: for smart material handling that eliminates unnecessary movement and boosts uptime.

Custom Automation Design: tailored solutions that fit your production goals and budget.

Operator Reskilling Support: training programs and tools to help your workforce grow into supervision roles.

Contact Verdusco Automation today!

📩 Get in touch now: https://www.verduscoautomation.com/contact